10 Ways Mining Drones Are Being Used

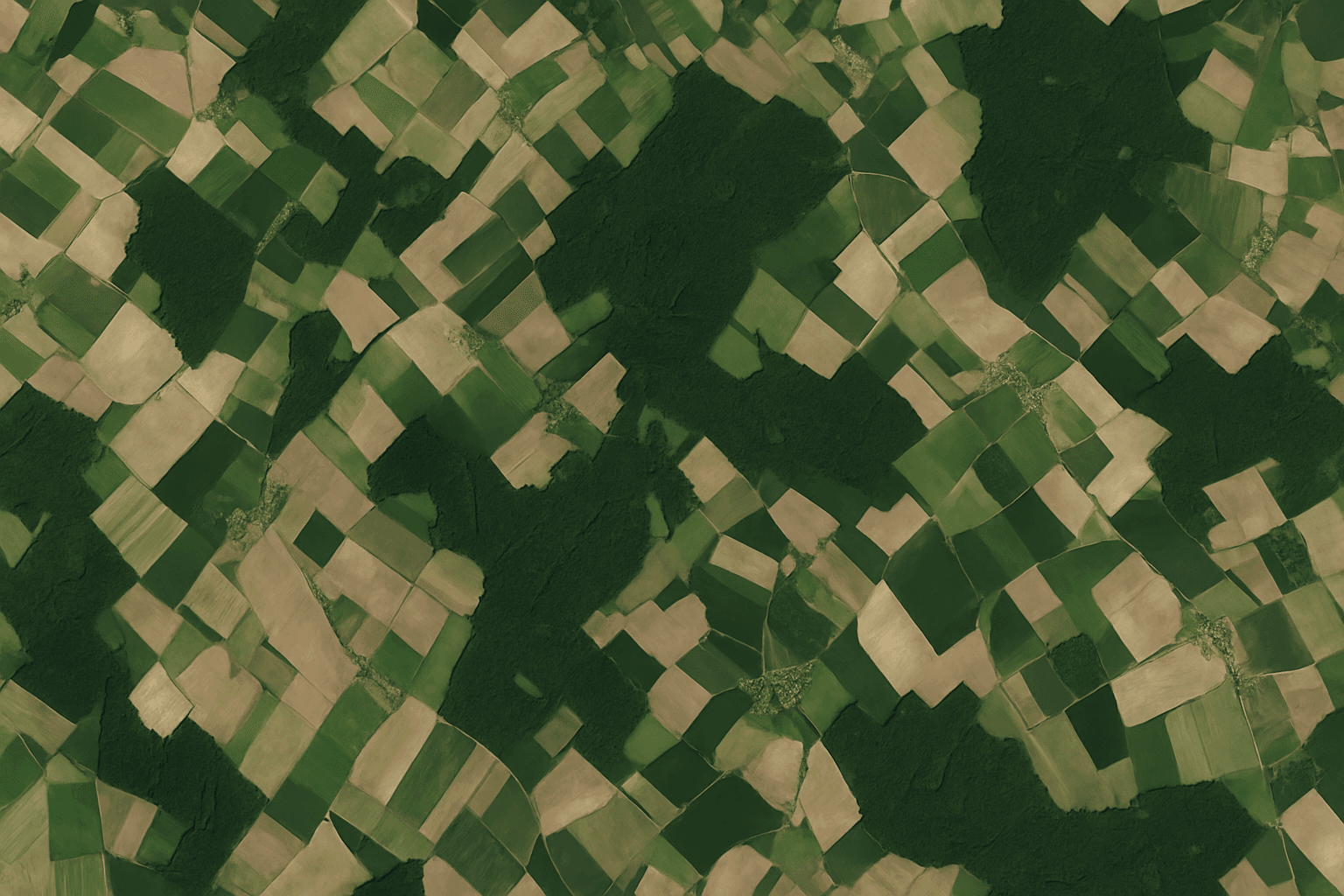

Mining drones are now essential equipment for modern mining operations. As drone mining technology evolves, the use cases continue to expand, supporting both underground and surface mining environments. Mine drones improve safety, reduce inspection time, and help mining companies make data-driven decisions with accurate aerial intelligence.

What Is a Mine Drone?

A mine drone is a specialized unmanned aerial system built for mining applications such as mapping, surveying, stockpile measurement, and equipment or structural inspections. Unlike standard hobby or commercial drones, mining drones are engineered for hazardous conditions and can operate in dust, vibration, zero-light environments, and GPS-denied areas.

Mining drones support multiple workflows, including:

Stockpile volume measurements

Orthomosaic mapping and DEM creation

Structural inspections and asset monitoring

Underground surveys in confined spaces

Ultrasonic and LiDAR-based thickness measurements

Mining operations involve high-risk environments where conditions change quickly. Traditional inspection methods require workers to enter unstable areas, climb equipment, or operate at height, which increases exposure to danger. Mine drones help reduce that risk by accessing zones where ground crews cannot safely go.

Modern drone mining platforms include advanced navigation systems with LiDAR, SLAM (Simultaneous Localization and Mapping), visual positioning systems, and obstacle avoidance. These capabilities allow the drone to fly underground or inside processing plants where no GPS signal is available.

While mine drones do not remove every hazard from the mining process, they reduce unnecessary human entry into hazardous zones, support predictive maintenance, and improve overall safety and operational efficiency.

The mining industry has rapidly embraced drone technology for better data collection, enhanced safety, and reduced operational costs.

Here are 10 major ways drones are transforming mining:

1. Volumetric Monitoring With Mining Drones

Volumetric monitoring is one of the most common and valuable uses of mining drones. It involves calculating the remaining quantity of overburden, ore, aggregate, or other mined materials stored in stockpiles. Because these stockpiles are large and continuously changing, manual measurement methods are time-consuming, costly, and often inaccurate.

Using mine drones for volumetric measurement provides fast, repeatable, and precise data. Drone mining workflows allow survey teams to capture stockpile data in minutes rather than hours. This helps mining companies track material movement, create audit-ready inventory reports, and reduce operational inefficiencies.

Mining drones equipped with photogrammetry or LiDAR sensors generate high-resolution 3D surface models. These models are processed using volume-calculation software that compares the stockpile surface against a known base layer, allowing accurate cut, fill, or depletion analysis. The result is a detailed measurement of remaining or moved material.

Mine drones can also:

Track excavation progress

Measure removed overburden volumes

Predict required backfill quantities

Monitor long-term stockpile changes

As more 3D datasets are collected, mining teams can analyze historical and real-time measurements to support planning, compliance reporting, and production forecasting.

For mining operations working with fluctuating ore grades and high-value materials, volumetric monitoring with mining drones provides a reliable, low-cost solution that improves accuracy across the full mining process.

2. Identifying Hazards With Mine Drones

Mining environments change rapidly, and hazards such as crumbling rock, gas exposure, dust buildup, and chemical residue can develop without warning. Both surface and underground mining operations face risks that challenge equipment and personnel. Mine drones help reduce exposure by allowing remote inspections and real-time monitoring.

Mining drones equipped with thermal, gas detection, LiDAR, and visual sensors can identify early warning signs before they become safety incidents. This prevents unnecessary worker entry into unstable areas and supports safety compliance requirements.

In surface mines, mine drones monitor slopes, benches, highwalls, and stockpile stability. They capture continuous datasets that help detect movement, cracking, or erosion. This supports proactive mitigation and improves operational continuity.

In underground mining, specialized drones can fly in dust, low-light, and confined areas using SLAM navigation without GPS. These drones create 3D maps that help locate blockages, evaluate stress zones, and analyze fractures in rock formations. This level of insight improves safety planning and reduces unplanned downtime.

Mine drones are now considered a critical mining tool for hazard identification because they support fast deployment, detailed inspection, and safer operational workflows.

3. Drilling and Blasting Assessment Using Mining Drones

Mining drones are also used throughout drilling and blasting activities to create accurate 3D models before and after blast events. These models serve as historical records and support engineering teams with data-driven insights.

Before blasting, drone mining workflows allow teams to capture the blast area and design pattern placement with precise measurements. This improves fragmentation, enhances productivity, and reduces material waste.

After blasting, an updated model is created to analyze fragmentation size, rock movement, and remaining hazards. These datasets help identify misfires, unstable areas, or excess material buildup. The information also supports refinement of future blast techniques.

Mine drones provide three key benefits for drilling and blasting workflow:

Improved accuracy in blast pattern design

Safety improvements by reducing human exposure

Faster assessment and optimization based on actual results

Using mining drones for drilling and blasting assessment ensures safer operations, better fragmentation outcomes, and improved consistency across the mining process.

4. Mine Monitoring and Planning With Mining Drones

Modern mining operations include many moving components that require continuous monitoring and careful planning to ensure productivity and safety. Mining drones help streamline these tasks by providing fast access to accurate site-level intelligence without interrupting operations. Drone mining workflows reduce travel time, improve inspection accuracy, and support decision-making across the entire mine life cycle.

Mining drones support planning and monitoring in several key areas:

Haul Road Design and Condition Monitoring

Haul roads are essential for transporting materials from the active mining zone to processing facilities or stockpiles. Heavy loads and frequent use create surface wear, rutting, and slope instability. Mining drones capture high-resolution data to evaluate grades, turning radius, drainage, and wear patterns. This supports maintenance planning and route optimization, improving fuel efficiency and equipment life.

Equipment and Asset Inspections

Mine drones allow remote inspection of conveyor systems, crushers, grinding mills, and other critical process equipment. These inspections can be performed without stopping production, enabling preventive maintenance and reducing unplanned downtime. Visual and thermal sensors help detect misalignment, belt wear, or structural fatigue early.

Worksite Security and Surveillance

Mine drones provide rapid situational awareness across large areas. They are used for perimeter monitoring, theft prevention, emergency response, and coordination with ground teams. Mining environments such as quarries and underground access points benefit from aerial visibility that would be time-consuming or dangerous to reach manually.

Environmental Monitoring and Compliance

Environmental monitoring is an increasing priority in mining. Mining drones help track runoff, dust movement, waste storage boundaries, and tailings dam conditions. Drones detect changes early and support compliance reporting, reducing environmental risks and improving sustainability practices.

5. Mine Development and Exploration With Mine Drones

Mine development and exploration traditionally required geologists and survey teams to enter unpredictable terrain and unknown underground conditions. This process was costly, slow, and often hazardous. Mining drones now support exploration work by mapping geological features, ventilation pathways, and structural conditions before humans enter.

Drone mining operations offer several benefits in exploration:

They map difficult-to-access areas safely

They identify fractures, voids, and blocked passages

They support early-stage feasibility and land development decisions

They provide 3D data that improves mine design accuracy

Mining drones are especially valuable for inspecting abandoned shafts and legacy mine workings, where stability is uncertain. High-resolution imagery, LiDAR models, and SLAM-based mapping provide a detailed view of underground conditions without requiring physical entry.

Using mine drones for development and exploration improves safety, reduces survey time, and lowers exploration costs while supporting responsible planning.

6. Processing Plant Inspections Using Mine Drones

Mining drones are increasingly used inside processing plants to inspect machinery and structural components without stopping production. This allows mining teams to collect accurate condition data while keeping critical equipment operational, improving uptime and reducing unnecessary shutdowns.

Mine drones equipped with visual, thermal, and ultrasonic sensors can inspect:

Feeders and Chutes: Identifying loose bolts, wear plates, and misalignment

Structural Welds: Detecting cracks, corrosion, or premature fatigue

Tanks and Pipes: Measuring wall thickness using ultrasonic payloads

Conveyor Belt Systems: Measuring heat levels and roller temperature for early failure detection

Material Flow: Comparing input and output volumes to monitor performance

Drones eliminate the need for scaffolding, ladders, or confined-space entry, making them a safer alternative to manual inspections while improving operational efficiency.

7. Emergency Response and Incident Assessment

Mining drones play a critical role in emergency response and post-incident evaluation. In events such as slope failure, equipment fire, flooding, or blocked underground areas, drones provide immediate visibility without placing personnel at risk.

Mine drones assist emergency teams by:

Assessing dangerous or inaccessible locations

Monitoring fire or heat signatures with thermal sensors

Guiding response teams with real-time aerial situational awareness

Documenting incidents for regulatory reporting

This accelerates decision-making and supports safer emergency planning.

8. Autonomous Monitoring and Smart Mining Workflows

As automation becomes standard across mining operations, autonomous mining drones now support repeatable flights without manual piloting. These systems operate on pre-programmed missions to monitor haul roads, blasting zones, slopes, and stockpiles on a scheduled basis.

Capabilities include:

Automatic takeoff, flight, and landing via docking stations

Scheduled volumetric monitoring

Autonomous environmental compliance tracking

Integration with GIS and digital mine management systems

Autonomous drone mining workflows reduce labor, standardize data quality, and support continuous optimization.

9. ESG Compliance and Sustainability Reporting

Environmental, Social, and Governance (ESG) reporting is now part of modern mining regulation and investor requirements. Mine drones help document compliance by capturing vegetation changes, water management performance, tailings dam condition, and land rehabilitation progress.

Drones simplify:

Visual proof of reclamation and overburden placement

Monitoring of carbon footprint reduction efforts

Tracking dust control and wastewater containment

Validating biodiversity restoration near active sites

This supports transparent reporting and helps mining companies meet regulatory standards and stakeholder expectations.

10. Digital Twin Development for Mine Sites

Mining drones contribute to creating digital twins of mines, enabling modeling of real-time operations in a dynamic 3D environment. Digital twins are used for planning, simulation, predictive maintenance, and operational optimization.

Drone data helps build and maintain the digital twin by:

Updating topography and bench elevation models

Integrating equipment health metrics from inspections

Tracking mining progress and structural changes

Supporting predictive modeling for slope stability and material flow

Digital twins enable mining teams to test scenarios, forecast risks, and improve long-term planning with real-world data.

Mining companies aiming to improve safety, efficiency, and monitoring accuracy can integrate drone mining solutions into their operations. XRTech Group provides industrial-grade mining drones, autonomous platforms, and geospatial integration services designed for modern mine environments.

The Benefits of Mining Drones in Modern Mining Operations

The value of mining drones continues to grow as drone mining technology advances and sensor capability expands. Mine drones now support essential workflows across surveying, safety, environmental compliance, and production management. As mining operations adopt automated drone systems, more use cases emerge that improve safety, reduce operational cost, and increase overall efficiency.

Below are the key benefits of mining drones in 2026:

1. Faster and More Accurate Aerial Data Collection

Mining drones capture high-resolution aerial data used to generate 2D orthomosaics, 3D site models, digital terrain models (DTM), and digital surface models (DSM). This level of detail supports planning, environmental reporting, and real-time operational analysis.

2. Reduced Need for Manned Aircraft or Manual Surveying

Mine drones replace helicopter flights and labor-intensive field surveying. Drone mining workflows lower cost, reduce scheduling delays, and provide consistent, repeatable data collection.

3. Improved Inventory and Volumetric Measurement Accuracy

Mining drones automate stockpile measurements and reduce the margin of error found in manual volume calculations. High-resolution LiDAR and photogrammetry models provide precise volumetric analysis for ore, overburden, aggregate, and waste material tracking.

4. Higher Inspection Frequency for Preventive Maintenance

Frequent drone inspections help detect developing issues—such as slope movement, equipment wear, or structural fatigue—before they disrupt mining operations. This supports predictive maintenance and reduces downtime.

5. Enhanced Environmental Monitoring and Compliance

Mining drones track environmental indicators such as erosion, water quality, vegetation regrowth, and tailings dam stability. This level of visibility supports ESG reporting, regulatory compliance, and responsible resource management.

6. Increased Safety and Reduced Worker Exposure

Mining drones reduce the need for workers to enter high-risk zones such as unstable slopes, deep pits, confined underground areas, or high structures. Remote inspection improves safety while still providing complete visibility of operational areas.

7. Faster Surveying and Operational Efficiency

Mine drones can survey large areas up to 30 times faster than traditional ground-based inspections. Faster data turnaround improves haul route planning, bench design, and operational decision-making.

8. Lower Operational and Inspection Costs

Mining drones reduce the cost of ground surveys, shutdown-based inspections, manual measurements, and manned flights. Over time, drone mining programs generate measurable cost savings while improving data quality.

9. Improved Security and 24/7 Monitoring

Mine drones support rapid surveillance of mining sites, access control zones, perimeter boundaries, and remote assets. They detect unauthorized access, illegal mining activity, and property damage in real time.

10. Access to Hard-to-Reach or Hazardous Locations

Mining drones can inspect steep slopes, deep voids, abandoned mine entries, and complex processing structures where human access is unsafe or impossible. Underground SLAM-enabled mine drones operate safely without GPS signals.

11. Superior Imaging and Data Quality With Specialized Payloads

Thermal, multispectral, ultrasonic, and LiDAR sensors provide advanced visual and engineering-grade measurements. Thermal drones detect overheating equipment, waste heat loss, or failure points in plant systems and electrical networks.

12. Real-Time Monitoring for Sustainability and Reclamation

Mining drones support long-term rehabilitation by tracking vegetation health, soil stabilization, drainage behavior, and landform changes. This evidence-based monitoring supports mine closure requirements and post-mining land use reporting.

Best Indoor Mine Drones

Indoor mining environments—such as underground drifts, haulage tunnels, ore passes, processing buildings, and maintenance workshops—require a different drone configuration than outdoor mining drones. While outdoor mining drones focus on endurance, mapping range, and weather resistance, indoor mine drones prioritize maneuverability, low-light performance, and reliable navigation without GPS.

Indoor mining sites often contain tight spaces, dust, vibration, low ceilings, and unpredictable airflow. Because these areas can pose immediate safety risks, indoor operations benefit from mine drones designed specifically for confined and GPS-denied environments.

Key Features Required for Indoor Mining Drones

Indoor drone mining environments require specialized design elements. The most important features include:

Full Obstacle Avoidance: 360° sensing to detect walls, pillars, equipment, and overhead obstructions

SLAM Navigation: Ability to fly with no GPS signal using LiDAR-based Simultaneous Localization and Mapping

Low-Light and Thermal Capability: Night-vision, thermal imaging, and high-ISO sensors for dark or dusty environments

Compact Form Factor: Small size for maneuvering through tight spaces, ore passes, and tunnels

Durability: Ability to withstand dust, vibration, moisture, and physical contact

Autonomous or Assisted Flight Modes: For consistent repeat inspections and reduced pilot error

These features allow the drone to operate safely, gather high-quality data, and perform repeated inspections with consistent accuracy.

1. Autel EVO II Enterprise V3: Best Compact Indoor Mining Drone

The Autel EVO II Enterprise V3 is well-suited for indoor mining because of its advanced sensing capabilities, compact footprint, and intelligent navigation systems. The aircraft includes 19 onboard sensors, including 12 visual sensors, ultrasound modules, and millimeter-wave radar, allowing it to detect obstacles and self-correct mid-flight.

Key capabilities include:

Autonomous obstacle avoidance for confined and complex structures

Real-time 3D mapping and stable positioning even in GPS-denied areas

640×512 thermal camera for hot spot detection, equipment monitoring, and underground safety checks

Enhanced low-light imaging using Autel’s Moonlight Algorithm 2.0 for improved visibility in dark tunnels and chambers

This mine drone is used for conveyor inspections, stockpile cavern mapping, processing plant surveys, and underground hazard detection where human access is limited or unsafe.

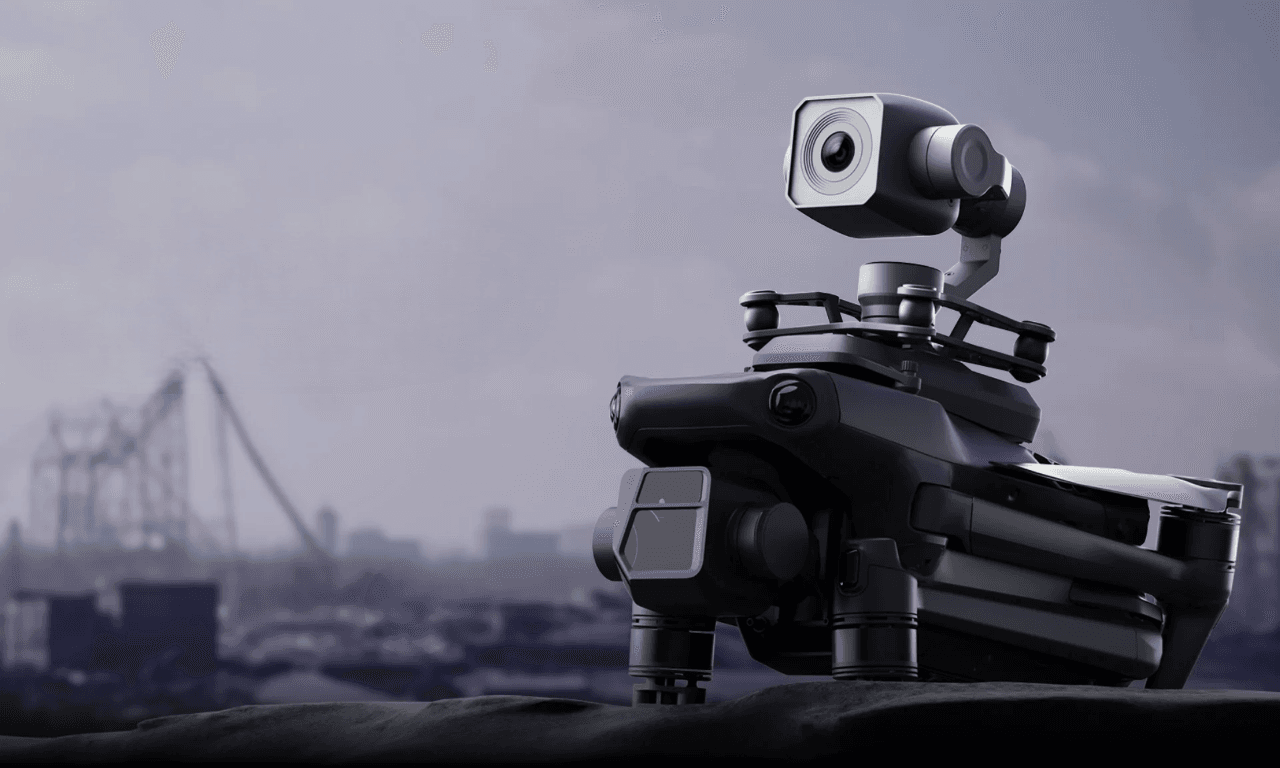

2. DJI Mavic 3 Thermal (M3T): Best Portable Indoor Mining Drone

The DJI Mavic 3 Thermal (M3T) is an ideal choice for indoor mining environments where mobility and fast deployment are critical. Its compact design allows operators to maneuver easily through processing plants, narrow access points, and underground chambers without requiring extensive flight clearance.

The M3T includes omnidirectional obstacle sensing, making it safer to operate in confined spaces with structural obstacles, suspended equipment, and low ceilings. Its 640 × 512 thermal camera supports inspections for overheating components, conveyor friction points, electrical faults, or mechanical wear. Despite its small form factor, the M3T delivers high-quality thermal analytics and detailed visual documentation suitable for maintenance, planning, and safety assessments.

This drone is widely used for:

Quick-response inspections

Routine maintenance checks

Thermal anomaly screening

Visual documentation for reporting

The lightweight and foldable design makes the M3T an excellent tool for onsite teams who require flexibility and ease of transport between underground access points, workshops, and operational areas

3. Autel EVO Max 4N: Best for Low-Light and GPS-Denied Environments

The Autel EVO Max 4N Drone for Mining is purpose-built for low-light and complex environments where GPS access is limited or unavailable, making it highly suitable for underground mines and enclosed industrial spaces. This mine drone includes a 640 × 512 thermal sensor paired with a starlight night-vision camera, providing superior imaging in dark, dusty, or restricted-visibility conditions.

The EVO Max 4N features advanced autonomous navigation systems that rely on LiDAR, visual positioning, and multi-directional sensing to maintain stable flight and avoid obstacles. This allows the drone to map complex underground workings, inspect aging infrastructure, or monitor high-risk equipment without requiring external positioning systems.

Typical use cases include:

Tunnel mapping and stope evaluation

Low-light infrastructure inspections

Hazard detection after blasting

Safety and emergency response

The EVO Max 4N is recognized as one of the most capable mine drones for deep underground inspections because it can operate safely and reliably where standard drones cannot navigate.

Best Outdoor Mining Drones

Outdoor mining environments require drone platforms built for long-range missions, large-area aerial mapping, live inspection work, and environmental monitoring across vast and rugged terrains. Outdoor mining drones must deliver endurance, precision, and multi-sensor compatibility to support demanding workflows such as volumetric measurement, mine planning, stockpile management, and compliance monitoring. These Drones operate in dust, heat, wind, and elevation changes, making durability and performance essential.

Key Features Required for Outdoor Mining Drones

Outdoor mining drones benefit most from the following capabilities:

Long-endurance flight time for large mine coverage in fewer missions

RTK positioning for centimeter-level survey accuracy

Multi-sensor payload support including LiDAR, thermal, RGB, multispectral, and methane gas detection

Strong weather and temperature tolerance suitable for desert, mountain, and open-pit mining environments

Long-range connectivity for beyond-visual-line-of-sight operations (where regulations allow)

AI-assisted mapping and automated flight planning for repeatable and accurate data collection

Obstacle avoidance and high-stability flight to operate in high-wind or dusty environments

These features support safe, efficient, and reliable drone mining workflows at scale.

1. DJI Matrice 350 RTK: Best High-Precision Outdoor Mining Drone

The DJI Matrice 350 RTK is one of the most widely used outdoor mining drones for high-accuracy surveying, mapping, and industrial inspection tasks. Built to operate in demanding mining environments, it supports extended missions and precise geo-referenced data capture.

Key capabilities include:

Up to 55 minutes of flight time for large-area coverage

RTK centimeter-level accuracy for volumetric calculations, engineering surveys, and mine planning

Triple payload capacity, allowing simultaneous use of LiDAR, RGB, and thermal sensors

Operating range from −20°C to 50°C, suitable for extreme mining environments such as open-pit mines, quarries, and desert operations

IP55-rated durability for dust, wind, and harsh conditions found in active mining sites

This drone is frequently deployed for:

Mine survey and mapping

Stockpile volumetric measurement

Road planning and haul road slope checks

Tailings dam inspection and safety monitoring

Thermal and environmental compliance audits

The M350 RTK helps mining organizations reduce surveying time, improve reporting accuracy, and streamline operational planning with consistent, high-quality geospatial outputs.

2. DJI Matrice 400: Best Long-Endurance Drone for Large Mining Sites

The DJI Matrice 400 is a top choice for mining operations that require long-duration flights, heavy payload capacity, and precision mapping over expansive outdoor environments. This platform is engineered for demanding industrial missions and supports advanced workflows such as LiDAR mapping, thermal inspections, methane gas detection, and long-range corridor monitoring.

The DJI Matrice 400 is a top choice for mining operations that require long-duration flights, heavy payload capacity, and precision mapping over expansive outdoor environments. This platform is engineered for demanding industrial missions and supports advanced workflows such as LiDAR mapping, thermal inspections, methane gas detection, and long-range corridor monitoring.

Key advantages include:

Up to 59 minutes of flight endurance, enabling fewer missions and reduced operational time

6 kg payload capacity, supporting multiple sensors simultaneously such as LiDAR + thermal + RGB

IP55 weather protection, engineered for dust, wind, and outdoor mining terrain

Reliable performance in extreme temperatures from −20°C to 50°C, suitable for harsh mining regions and desert climates

The DJI Matrice 400 is ideal for:

Large-scale geospatial mapping and volumetric analysis

Tailings dam monitoring and hazard detection

Environmental compliance reporting

Exploration corridor mapping and topographic modeling

With its payload flexibility and long operational range, the Matrice 400 provides mining teams with high-quality data that supports decision-making, safety planning, and long-term operational efficiency.

3. DJI Matrice 300 RTK: Trusted Workhorse for Mining Inspections

The DJI Matrice 300 RTK remains one of the most widely used outdoor mining drones because of its reliability, high-precision capabilities, and strong performance in industrial environments. It is frequently selected for outdoor thermal inspections, volumetric mapping, and safety monitoring tasks where detection accuracy is essential.

Notable capabilities include:

55-minute flight time for extended mapping missions

Extreme temperature tolerance from −20°C to 50°C, ensuring dependable operation in outdoor mines

High-sensitivity thermal capability for detecting subtle heat anomalies, equipment faults, or slope instability

Compatibility with the Zenmuse H20T multi-sensor payload, which combines RGB, LiDAR support, laser rangefinding, and radiometric thermal imaging

The Matrice 300 RTK supports common mining workflows such as:

Thermal hazard detection

Stockpile measurement and mine planning

Tailings dam stability analysis

Environmental monitoring for ESG compliance

Conveyor, plant, and structural inspections

Because of its long-term reliability and advanced multi-sensor capabilities, the Matrice 300 RTK continues to be a core platform in professional mining drone programs.

4. Autel ALPHA: Best for Long-Range Mining Surveillance

The Autel ALPHA is designed for large-scale drone mining operations where extended range, high-resolution imaging, and persistent monitoring are priorities. This platform performs well in remote and rugged mining locations due to its long-distance communication system and efficient power management.

Key performance benefits include:

50-minute flight endurance, supporting large-area surveying and stockpile mapping

15 km transmission range, ensuring reliable remote operation in expansive open-pit or quarry environments

A 640×512 thermal camera that identifies heat anomalies, equipment performance issues, and safety risks

56x hybrid zoom, enabling close inspection from a safe altitude without interrupting mining activity

The Autel ALPHA is well suited for:

Large open-pit mapping

Infrastructure and haul road monitoring

Emergency response and security patrols

Tailings dam inspection and hazard identification

Its long-range capability and multi-sensor flexibility make it one of the strongest choices for operations requiring persistent data collection and remote situational awareness.

5. Autel EVO Max 4T: Best All-Purpose Outdoor Mining Drone

The Autel EVO Max 4T delivers a balance of durability, thermal capability, and advanced navigation systems, making it highly effective for dynamic and hazardous mining environments. It is engineered for reliable performance in complex flight zones and supports precise inspection workflows.

Standout features include:

640×512 thermal sensor for detecting overheating equipment, fault zones, and geotechnical instability

50MP high-resolution RGB camera for detailed visual mapping and compliance documentation

Operational temperature range from −20°C to 50°C, supporting year-round outdoor mining operations

720° obstacle avoidance and advanced anti-jam protection, enabling stable flight in high-interference zones

The EVO Max 4T is commonly deployed for:

Structural inspection of conveyor belts and crushers

Blast assessment and post-excavation surveying

Real-time hazard detection and operational safety checks

Autonomous aerial monitoring of mining equipment and vehicle movement

With a focus on precision, safety, and reliability, the Autel EVO Max 4T has become a strong choice for mining teams upgrading from manual monitoring to autonomous drone-based workflows.

Specialized Thermal Capabilities for Mining

In mining, thermal imaging drones are essential for:

• Hotspot Detection: Monitoring machinery, electrical panels, and processing equipment for overheating or wear.

• Safety and Integrity: Checking infrastructure integrity, such as detecting deformation and subsidence of tailings dams and pipelines using specialized data like InSAR technology (though InSAR is satellite-based, it monitors the assets often inspected by these drones).

• Environmental Compliance: Drones can monitor environmental changes and detect issues like chemical leaks using thermal and advanced spectral analysis.

The robust DJI Matrice series (M300/M350/M400) is often the preferred choice for such demanding industrial applications due to their exceptional endurance, heavy payload capacity, and compatibility with the most advanced multi-sensor thermal cameras (Zenmuse H20T, H30 series)

Best Mine Drone Software

Mining operations rely on precise, repeatable, and high-accuracy data to support planning, safety, and reporting. The best mine drone software solutions help convert aerial data into measurable outputs such as 3D models, stockpile volumes, mine maps, and compliance documentation. These tools support core workflows across drone mining, making mining drones more useful for volumetric analysis, hazard detection, and site optimization.

Below are leading platforms trusted by the mining sector.

DroneDeploy — Best All-Purpose Mapping Platform for Mining Drones

DroneDeploy is widely used in mining drones workflows because it supports stockpile measurement, haul road evaluation, site mapping, and environmental documentation. Its automated cloud processing reduces manual work and helps mine teams make fast decisions using accurate visual, LiDAR, or thermal data.

Top Features:

Stockpile inventory management with automated volumetric reports

Mine planning and excavation insights to support forecasting

Safety and compliance reporting for environmental and operational controls

Centralized operations management across multiple mine sites

DroneDeploy helps mining companies streamline workflows by converting aerial datasets into actionable operational outputs.

Pix4D — Best Software for Precision 3D Mapping and Modeling

Pix4D is favored for high-precision photogrammetry and 3D modeling. The platform uses image-based processing to support mine drones during planning, volumetric calculation, and hazard analysis. Pix4D ensures stability and precision in environments where repeatability and measurement accuracy matter.

Top Features:

Forecast geotechnical hazards using data-driven analysis

Accurate automatic stockpile volume calculation

Asset lifecycle management aligned with mine development stages

Generate high-resolution interactive 3D maps and models

Pix4D enables consistent geospatial outputs essential for safe extraction, surveying, and resource reporting.

Propeller — Best Platform for Survey-Grade Accuracy in Mining

Propeller is a leading software platform designed to convert flight data from mining drones into accurate engineering outputs. Its geospatial processing capability ensures measurable, repeatable results suitable for planning, engineering validation, and mine reporting.

Top Features:

Quick and frequent drone surveys with automated pipelines

Full documentation of lifecycle stages from exploration to reclamation

Simplified inventory and stockpile measurement management

Cloud collaboration for surveyors, engineers, and operations teams

Propeller helps mine operators track site progress, movement, and material displacement in near real-time.

Skycatch — Best for Automated Processing and Fast Data Delivery

Skycatch offers automation-focused software for large, complex mine environments. The platform integrates fleet management, AI-powered analysis, and fast processing pipelines suitable for large-scale surface mines or hard-to-access terrain.

Top Features:

Fast time-to-data for operational decision-making

Eliminates GCP requirements, improving safety during capture

Proven five-centimeter accuracy across all axes

Offline or cloud-based processing

High-fidelity 3D models of vertical surfaces such as benches and walls

Skycatch is well-suited for mining teams requiring automation, accuracy, and scalable workflows across multiple sites.

DJI and Autel Mining Drone Case Studies

Both DJI drones and Autel drones are widely deployed in drone mining workflows, especially for mapping, surveying, stockpile volume measurement, monitoring safety hazards, and industrial inspections. Real-world case studies demonstrate how mine drones improve operational efficiency, accuracy, and worker safety compared to traditional manual surveying and measurement methods.

DJI Mining Case Studies

DJI platforms are frequently used in large mining operations due to their advanced payload ecosystem, including RTK/PPK survey tools, LiDAR sensors, thermal imaging, and photogrammetry payloads. These capabilities make DJI one of the most adopted brands in mining drones programs globally.

Key examples include:

BHP Mitsubishi Alliance (BMA)

BMA integrated the DJI Matrice 350 RTK into its mine surveying workflows to capture accurate 3D spatial datasets. These datasets support:

Mine design and haul road planning

Dragline and drilling alignment

Highwall stability assessments

The drone workflow increased survey precision and improved turnaround time for engineering teams.

Ferrexpo Yeristovo Mining

This iron ore operation deployed customized DJI mine drones to improve safety and efficiency during blasting operations. The drones performed:

The site reported a 90 percent reduction in surveying time, replacing labor-intensive manual checks.

Northern Star Resources — KCGM Super Pit

The operator uses the DJI Matrice 400 paired with the Zenmuse L3 LiDAR system to survey a large open-pit mine measuring over 650 meters deep. A full scan that once required hours of manual data collection is now completed in 15 minutes, enabling weekly multi-temporal digital modeling.

Poltava Mining via DroneUA

Underground applications were validated when a DJI Matrice 210 RTK conducted successful flights 410 meters below ground. The RTK module helped maintain positioning despite magnetic interference, enabling accurate 3D mine mapping underground.

Autel Drone Case Studies and Applications

Autel Robotics platforms are increasingly used in mining due to long-endurance flights, cost efficiency, high-altitude capability, and thermal imaging performance. The EVO II series and Dragonfish VTOL are frequently used for surveying remote sites and large mining corridors.

Key deployments include:

High-Altitude Mining Operations

Many large mines in South America operate above 4,000 meters elevation. The Autel EVO II series supports high-altitude takeoff up to 5,000 meters, maintaining endurance with minimal performance loss. This makes Autel a strong option for elevated mining regions.

Accuracy Benchmark Study

A third-party evaluation by 3Dsurvey compared the Autel EVO II Pro 6K RTK with the DJI Phantom 4 RTK across two quarry sites. Results showed:

Both platforms produced survey-grade accuracy suitable for mine engineering use

The Autel drone operated more quietly during long missions

The DJI unit executed faster automated turn sequences

The final recommendation: selection depends on budget, mission profile, and sensor requirements—not capability gaps.

General Mining Use Cases

Autel positions its systems for:

For very large mine footprints, the Autel Dragonfish VTOL provides fixed-wing efficiency, extended flight endurance, and suitability for long-range monitoring of haul roads, pit boundaries, and remote stockpiles.

Why Choose XRTech Group to Buy Mine Drones

Choosing XRTech Group for mining drone procurement offers several strategic advantages for mining companies looking for industrial-grade performance, support, and integration. XRTech stands out because it provides:

A curated catalog of proven mining drones — including both compact indoor drones and heavy-duty outdoor platforms — optimized for surveying, stockpile measurement, thermal inspection, and mapping.

Access to customization and payload integration (LiDAR, thermal, gas detectors, RTK modules) tailored to specific mining needs.

Expertise in drone deployment workflows, safety protocols, and regulatory compliance, reducing onboarding time and improving operational reliability.

Support for downstream processes: geospatial data integration, mapping, volumetric analysis, environmental monitoring, and report outputs — ensuring the drone investment drives long-term value, not just one-time data capture.

Global support and maintenance infrastructure suitable for remote or challenging mining environments, ensuring uptime and mission readiness even in harsh conditions.

With XRTech Group, mining operations gain not just hardware — but a full drone-asset solution enabling safer, more efficient, and more accurate mining processes.

Conclusion

In 2026, mining drones have become an essential part of modern mining workflows. They deliver faster, safer, and more accurate data for everything from stockpile measurement and terrain mapping to safety monitoring and environmental compliance. Whether operating underground tunnels or open-pit mines, mining drones support better decision-making, cost reduction, and operational resilience.

Platforms like DJI and Autel offer proven reliability across both indoor and outdoor mining environments. However, success depends on choosing the right drone, payloads, and workflows. That is why partnering with a specialized provider like XRTech Group makes sense. XRTech delivers hardware, integration, data processing, and long-term support — giving mining companies a comprehensive solution rather than a one-off purchase.

If you are ready to upgrade your mining operations with drone technology that drives safety, efficiency, and long-term value, XRTech Group is equipped to support you every step of the way. Contact us Now!

Frequently Asked Questions (FAQs)

Q1: What kinds of drones are best for mining operations?

A: Mining operations benefit from both compact indoor drones for tunnels and processing areas, and large outdoor drones with long endurance and multi-sensor payloads for surface mines, mapping, and stockpile measurement.

Q2: Can mine drones replace traditional surveying and manual inspections?

A: Yes. Drone-based surveys are faster, safer, and often more accurate than ground-based inspections or manned aircraft. They reduce human exposure and deliver high-resolution data for planning and compliance.

Q3: What sensors are important for mining drones?

A: Key sensors include LiDAR for terrain mapping, thermal cameras for hotspot detection, RGB and multispectral cameras for visual and environmental monitoring, and RTK/PPK modules for precise geolocation.

Q4: Are mining drones useful in underground or GPS-denied environments?

A: Yes. Some indoor mining drones are built with SLAM navigation and obstacle avoidance systems that make them suitable for tunnels, shafts, and processing plants without GPS.

Q5: How does drone data support mine planning and environmental compliance?

A: Drone data delivers accurate 3D models, volumetric measurements, slope stability analysis, tailings dam monitoring, reclamation tracking, and environmental impact mapping, supporting regulatory compliance and ESG reporting.

Q6: Can drone programs reduce long-term operational costs?

A: Yes. By minimizing manual labor, reducing downtime, improving inventory accuracy, and enhancing monitoring efficiency, mining drones deliver cost savings over time.

Q7: Is training and support necessary for mining drone deployment?

A: Yes. Proper training, payload integration, maintenance schedules, and data management workflows are crucial. Service providers like XRTech Group offer full support to ensure reliable scanning and inspection operations.

Q8: How often should drone surveys be performed in a mine?

A: It depends on operational needs. Frequent volumetric updates, slope stability checks, and environmental monitoring may require weekly or monthly flights. Stability checks after blasting or heavy rains might prompt additional surveys.

Q9: Are drone inspections accepted by regulatory authorities as valid data?

A: Increasingly, yes. Many regulators accept drone-based survey data, especially when it is generated using certified equipment and properly processed. High-precision drones with RTK/PPK and validated output formats support regulatory reporting needs.

Q10: Can drones help with mine closure and reclamation planning?

A: Yes. Drones capture terrain changes, stockpile removal progress, landform reshaping, and vegetation regrowth. This data supports final rehabilitation reports, environmental compliance, and safe land reuse post-mining.

The

The