The Best Drone in a Box for Construction: Your Easy Guide for 2026

Imagine a special box that holds a drone, charges it, and sends it out to work all by itself! This amazing technology is called a drone in a box. In the world of construction, these smart systems are changing how work is done, making things safer, faster, and more efficient. This guide will help you understand what a drone in a box solution is, why it is so helpful for building projects, and what to look for when choosing the best one in 2026.

Construction sites are busy places with lots of moving parts and sometimes risky areas. Traditionally, people had to walk around these sites, climb tall structures, or use helicopters to get a full view. Now, thanks to drone boxes, a lot of this work can be done from a computer screen, even miles away. This new way of working is not just cool; it brings many real benefits that we will explore. We will discuss why these drone boxes are becoming a must-have tool for modern construction.

The idea of an autonomous drone Box that can fly itself, gather information, and then return home to charge is quite new and exciting. It means that tasks like checking progress, making sure workers are safe, or looking at how materials are being used can be done regularly and automatically. This updated guide for 2026 will provide fresh insights into how these systems are being used and why they are considered a smart investment for construction companies looking to improve their operations.

Visit XRTech Group Drone-in-a-Box Solutions

Top 10 Drone-in-a-Box Solution

How Does a Drone in a Box Work?

A drone in a box solution is much more than just a drone and a simple storage case. It is a complete system that allows drones to operate without a person needing to be right there. Think of it as a tiny, smart hangar for a drone.

-

The "Box" Itself: This is a special, often weather-resistant, container that sits on the ground. It protects the drone from rain, dust, and extreme temperatures. Inside, there is a charging station, and sometimes even a system to swap batteries automatically.

-

The Drone: A special drone is kept inside the box. These drones are often designed to be smart and can fly pre-planned routes, collect data (like pictures or videos), and avoid obstacles all by themselves. They are an autonomous drone Box.

-

The Brain (Software): A special computer program is used to tell the drone what to do. This software is often cloud-based, meaning it works over the internet. You can plan missions, set up flying routes, and schedule when the drone should fly, all from a computer far away.

-

Sending Information: The drone sends the information it gathers (like pictures or videos) back to the ground through a special connection. This data is often sent to the cloud, so it can be looked at from anywhere.

-

Automatic Takeoff and Landing: When it's time to fly, the drone box opens, and the drone takes off. When its job is done, it flies back to the box and lands by itself. It then charges its batteries or has them swapped out automatically, ready for its next mission. This makes it a true drone in a box solution.

This whole system allows for tasks to be done repeatedly, on a schedule, and with very little human help. This is what makes a drone in a box so powerful for construction sites.

Top 10 Best Construction Companies in Dubai

Best Drone in Construction

Why Are Drone in a Box Solutions Needed in Construction?

Construction is a complex business, and finding ways to make it safer, faster, and smarter is always important. This is where drone boxes truly shine. They bring many benefits that older ways of working just cannot match.

1. Keeping Workers Safe

Safety is the most important thing on a construction site. Drones can go to places that might be dangerous for people.

-

Inspecting High Places: Instead of sending workers to climb tall buildings or inspect dangerous roofs, a drone in a box can do it. This reduces the risk of falls or other accidents.

-

Checking Unstable Areas: After a blast or in an area that might collapse, a drone can be sent in first to check for dangers, keeping human lives out of harm's way.

-

Monitoring Hazardous Environments: Drones can inspect areas with poor air quality, loud noises, or moving heavy machinery, which would otherwise be risky for workers.

By keeping people out of risky situations, the autonomous drone Box greatly improves safety on construction sites.

2. Making Work Faster and More Efficient

Time is money in construction, and drone boxes help save both.

-

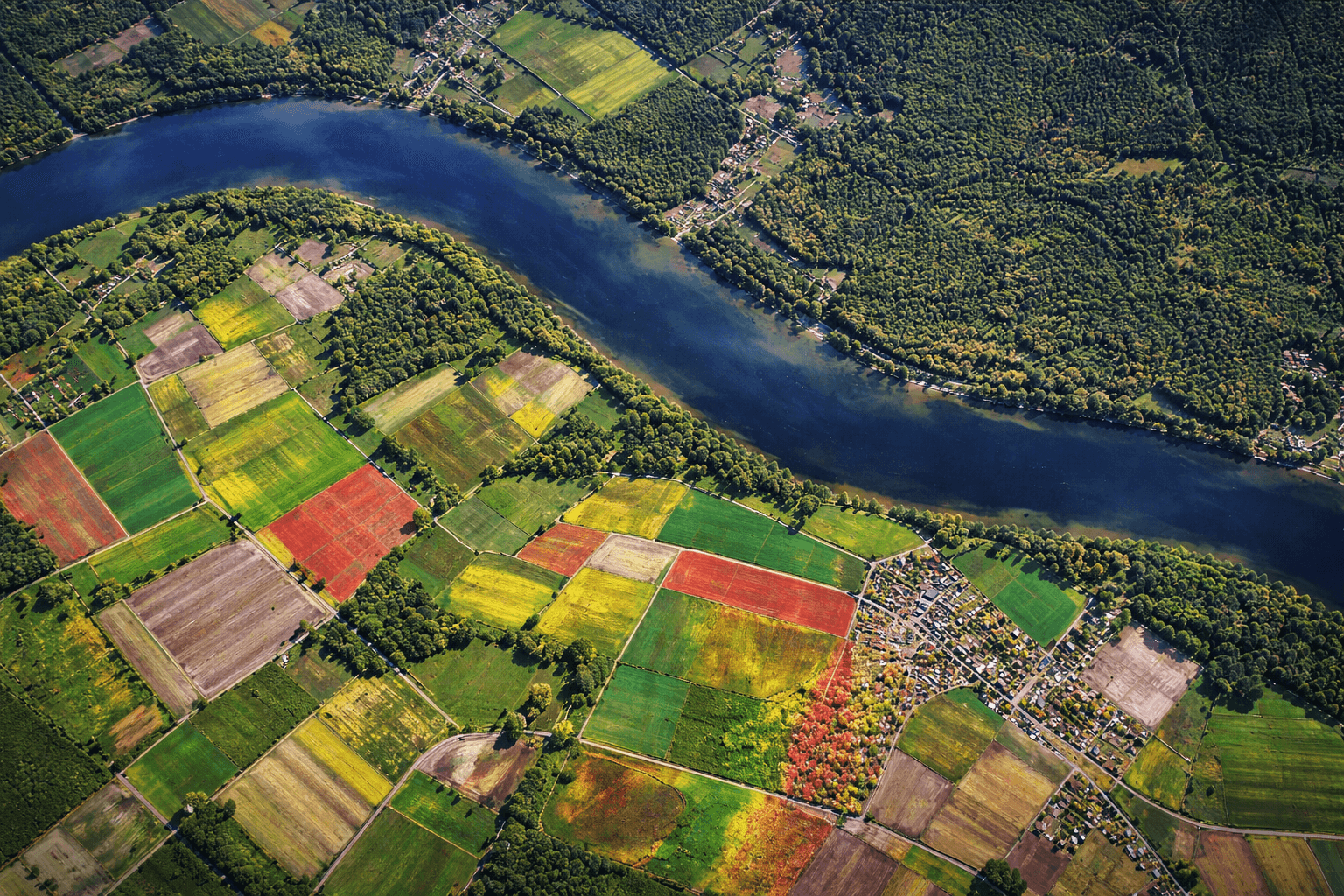

Quick Site Surveys: A drone can map a large construction site in minutes or hours, something that would take days for people on the ground. This quick data helps start projects faster.

-

Daily Progress Checks: Drones can fly the same path every day to take pictures. This allows managers to see how work is progressing, spot delays early, and make sure everything is on schedule. This regular, automated monitoring is a core benefit of a drone in a box solution.

-

Automated Inspections: Instead of manual checks, an autonomous drone Box can carry out repeated inspections of things like power lines, pipelines, or large structures automatically. This saves a lot of labor time.

The speed and automation provided by a drone in a box lead to smoother operations and faster project completion.

3. Getting Better and More Data

Construction projects need lots of accurate information. Drone boxes are excellent at collecting this data.

-

High-Quality Pictures and Videos: Drones can take very clear pictures and videos from different angles, giving a complete view of the site.

-

3D Models and Maps: The data collected by drones can be turned into exact 3D models of buildings, piles of dirt, or the entire site. These models help engineers plan and check work accuracy. This is a powerful use of drone boxes.

-

Thermal Imaging: Some drones can see heat. This is useful for finding leaks in pipes, checking electrical systems, or spotting hidden problems on a construction site.

-

Consistent Data Collection: Because the drone flies the same path every time, the data collected is very consistent. This makes it easier to compare information over time and see changes.

Better data leads to better decisions, fewer mistakes, and overall higher quality construction. The continuous data stream from an autonomous drone Box is invaluable.

4. Saving Money

While setting up a drone in a box solution costs money at first, it can save a lot in the long run.

-

Less Need for Manual Labor: Many tasks that used to need human workers (like surveying small areas or simple inspections) can now be done by the drone, freeing up workers for more complex jobs.

-

Fewer Delays: By quickly spotting problems or delays, construction managers can fix them before they become big and expensive issues.

-

Reduced Equipment Costs: In some cases, drones can replace more expensive equipment like cranes or specialized vehicles for certain inspections.

The overall efficiency and problem-solving power of a drone in a box contribute to significant cost savings on construction projects.

DJI Dock 2

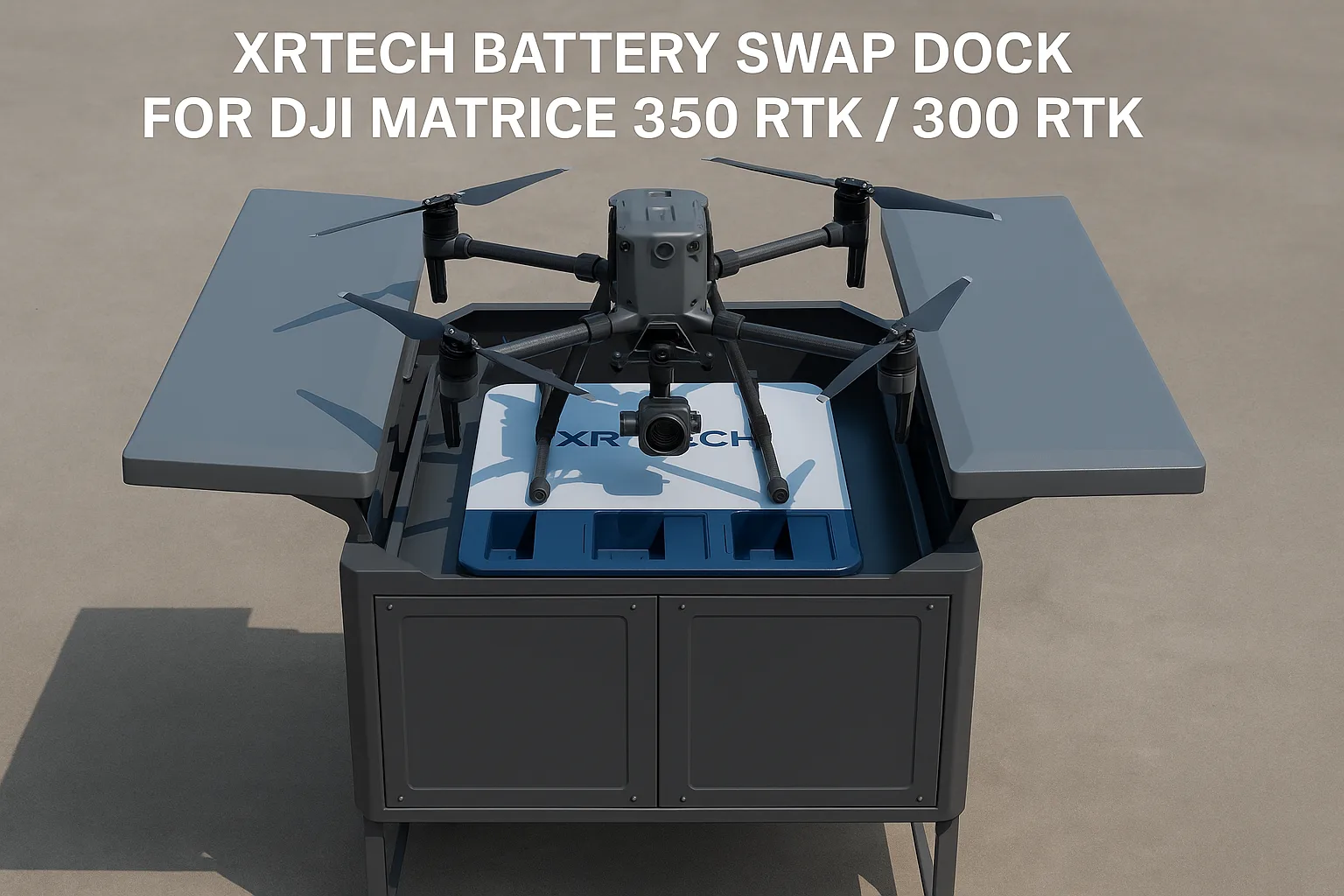

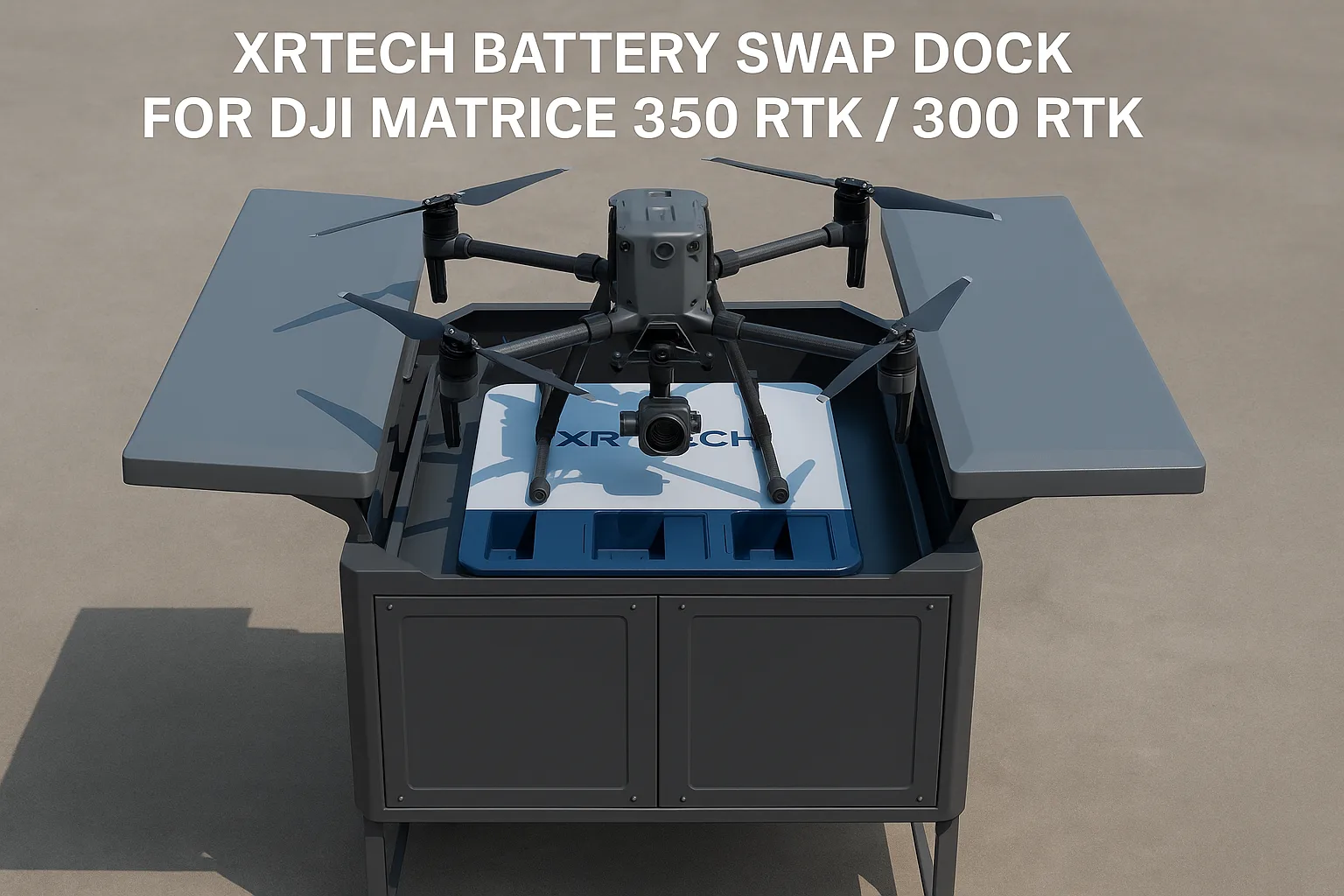

XRT Swap Dock for DJI Matrice 350 RTK

XRT Swap Dock for DJI Matrice 30 Series

Key Features to Look for in a Drone in a Box for Construction

Choosing the right drone in a box solution for a construction site means thinking about several important features. Not all drone boxes are the same, and picking the right one can make a big difference in how well it helps your project. Here are the top things to consider:

1. Durability and Weather Resistance

Construction sites are tough environments. A drone box needs to be strong and able to handle different weather conditions.

-

IP Rating: Look for a high IP (Ingress Protection) rating, like IP55 or IP56. This number tells you how well the box is protected from dust and water. Higher numbers mean better protection, which is crucial for a construction drone box that will be outside.

-

Temperature Tolerance: The system should work in a wide range of temperatures, from very cold winters to hot summers. Knowing the temperature limits (e.g., -25°C to 45°C) is important.

-

Rugged Construction: The physical build of the drone box should be tough enough to withstand vibrations, accidental bumps, and general outdoor wear and tear.

2. Operational Range and Coverage Area

How far the drone can fly from its box and how large an area it can cover are key factors for large construction sites.

-

Operational Radius: This tells you how far the drone can fly away from its home box and still communicate reliably. A larger radius (e.g., 10km or 15km) means more ground can be covered from a single deployment point for the drone in a box solution.

-

Battery Life/Flight Time: A longer flight time means the drone can cover more area or complete more tasks before needing to return to the drone box for a charge.

-

Beyond Visual Line of Sight (BVLOS) Capability: Some advanced systems can fly beyond where a human operator can see them. This is very important for large or remote construction sites, but it requires special permits. An autonomous drone Box often offers BVLOS.

3. Drone Compatibility and Payloads

The kind of drone that fits into the drone in a box and what tools it can carry (payloads) are very important.

-

Specific Drone Models: Some drone boxes are made for certain drone models (e.g., DJI Matrice series, Autel EVO series). Ensure the box supports the drones you want to use.

-

Camera Systems: Look for drones with advanced camera systems, including wide-angle, telephoto (for zooming in), and thermal imaging cameras (for seeing heat). Night vision and IR-cut filters can also be helpful for 24/7 operations.

-

Laser Rangefinders: These are great for measuring distances accurately, which is very useful for surveying and mapping on a construction site.

4. Charging and Battery Management

How quickly the drone can get back into the air after landing is crucial for continuous operations.

-

Automatic Charging: The drone box should automatically charge the drone's batteries when it lands.

-

Battery Swapping: The best systems offer automated battery swapping. This means a robot arm inside the drone box quickly changes the drone's depleted battery for a fresh one, allowing the drone to be back in the air in just a few minutes (e.g., 3 minutes). This greatly reduces downtime.

-

Backup Power: A built-in backup power system is important to keep the drone box running even if the main power goes out.

5. Accuracy and Precision

For construction, measurements need to be very accurate.

-

Centimeter-Level Positioning (RTK/D-RTK): Look for systems that use RTK (Real-Time Kinematic) or D-RTK technology with dual antennas. This allows the drone to know its position with centimeter-level accuracy, which is vital for precise mapping and surveying tasks.

-

Landing Accuracy: The drone box should ensure very precise landings (e.g., ±0.05m accuracy). This prevents damage to the drone and ensures it successfully docks for charging or battery swapping. Nighttime fill lights can help with precision landings in low light.

-

High Accuracy Data Outputs: The final maps and models created from the drone data should meet strict accuracy standards (like CE90 and RMSE specs), ensuring reliable data for engineering and planning.

6. Data Management and Connectivity

How the data is sent, stored, and managed is crucial.

-

Cloud-Based Platforms: Most advanced drone in a box solutions use cloud platforms (like DJI FlightHub 2 or XRT Cloud Box M2). This allows remote planning, real-time monitoring, and automatic data uploads, making data accessible from anywhere.

-

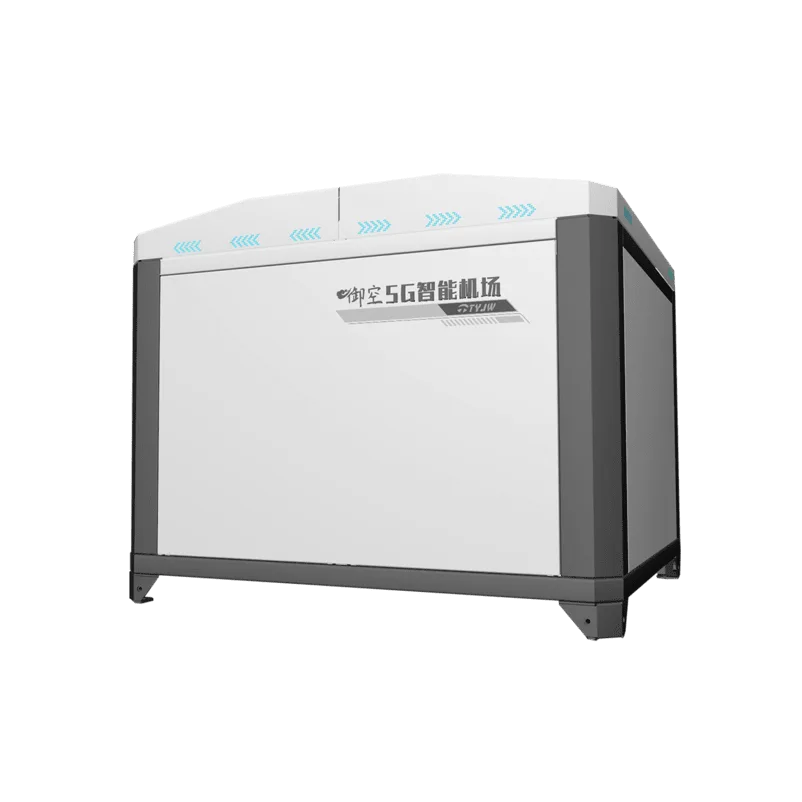

Connectivity (e.g., 5G): Strong and reliable communication is needed between the drone box and the control center. Some systems use 5G connectivity for real-time data streaming and remote control.

-

Compatible File Formats: Ensure the system delivers data in formats you already use (e.g., GeoTIFF, SHP, DWG) for easy integration with your GIS or CAD software.

7. Autonomy and Remote Operation

The core idea of a drone in a box is self-sufficiency.

-

Automated Mission Planning: The ability to schedule, monitor, and execute aerial operations without human intervention is key. This is the heart of an autonomous drone Box.

-

Remote Control: Operators should be able to control and monitor the drone and its missions from a distant location.

-

Environmental Monitoring System: The drone box should have sensors to track external conditions like heat index, rainfall, snow, and wind. This allows the system to intelligently adjust operations for safer flying.

8. Intelligent Features for Enhanced Performance

Modern drone boxes often come with smart features that boost their capability.

-

Onboard Modeling: Some drones can process 2D and 3D maps right on the drone itself, reducing the need for external software and speeding up data delivery.

-

Predictive Analytics: Advanced systems might use smart computer programs to analyze data and predict potential issues, allowing for proactive maintenance or planning.

-

Multi-Point Hopping: For some XRTech Group solutions, drones can move between different drone boxes at various sites, allowing for extended coverage over very large areas.

DJI Dock 2 – Product Page

XRT Automated Battery Swapping Station for DJI M30/M30T

XRT Automated Battery Swapping Station for DJI M350/M300

Autel Dragonfish Nest

Autel EVO Nest

Leading Drone in a Box Solutions for Construction from XRTech Group

XRTech Group offers several cutting-edge drone in a box solutions that are perfect for the demands of the construction industry. These systems are designed to provide reliability, precision, and autonomy, making them ideal for improving efficiency and safety on your projects.

1. DJI Dock Series (Offered by XRTech Group)

DJI is a well-known name in drones, and their Dock series offers powerful drone in a box systems.

-

DJI Dock 2:

- This is a newer, lighter, and smaller drone box compared to earlier versions.

- It works perfectly with DJI Matrice 3D and Matrice 3TD autonomous drones.

- The box is tough, with an IP55 rating for dust and water protection.

- It can operate in temperatures from -25°C to 45°C.

- Drones can fly up to 10km away from the box.

- Centimeter-level positioning is provided by dual RTK antennas for very accurate data.

- It has a system to monitor the environment and built-in backup power.

- Seamlessly connects to DJI’s FlightHub 2 platform for automated flights, landings, and data uploads.

- Benefit for Construction: Ideal for regular site inspections, surveying large areas quickly, and monitoring security around construction perimeters without needing a person on site.

-

DJI Dock 3:

- This system takes autonomous drone operations to the next level, built for extreme toughness.

- It supports DJI Matrice 4D and Matrice 4TD drones, which are also very durable (IP55 rated).

- The Dock 3 itself has an IP56 rating and can work in even harsher environments, from -30°C to 50°C.

- Drones can fly for up to 54 minutes.

- Features advanced multi-camera systems (wide-angle, telephoto, laser rangefinder) for detailed inspections.

- The 4TD model includes night vision, an IR-cut filter, and a thermal imaging camera, which are great for 24/7 operations on a construction site.

- It offers horizontal calibration and cloud-based alignment for stable flights.

- Benefit for Construction: Perfect for high-stakes missions like emergency response on large construction sites, detailed infrastructure inspections (e.g., bridges, high-rise buildings), and ongoing safety monitoring where thermal imaging can spot issues. This is a top-tier autonomous drone Box.

Get a Quote for DJI Dock 3

2. XRT Battery Swap Dock Drone in a Box Solutions (XRTech Group's Own)

XRTech Group also offers its own specialized XRT Battery Swap Dock drone box systems, designed for continuous operation and advanced remote capabilities. These are uniquely built to maximize uptime.

-

XRT Battery Swap Dock for DJI Matrice 350 RTK / 300 RTK:

- This drone box solution is made specifically for DJI Matrice 350 RTK and DJI 300 RTK drones, popular for their power and precision.

- It is a high-performance battery swapping station, meaning drone batteries are changed automatically.

- The best part: batteries are swapped in under 3 minutes, significantly reducing downtime and allowing continuous missions.

- It supports a 15 km operational radius.

- When paired with the XRT Cloud Box M2, it uses 5G connectivity for real-time data streaming and multi-point hopping between different sites. This is a very advanced feature for managing multiple locations from one central point.

- Landing accuracy is very high (±0.05m) and includes a nighttime fill light for safe, precise landings even in the dark.

- Advanced environmental sensors track video, heat index, rainfall, snow, and wind, allowing the drone box to adjust operations smartly.

- Applications for Construction:

- Geomatics & Surveying: Great for accelerating mapping and land assessments with high accuracy.

- Powerline Inspection: Efficiently cover large utility areas, which are often part of new construction or infrastructure projects.

- Oil & Gas Monitoring: Safely inspect pipelines, rigs, and wells on industrial construction sites.

- Firefighting & Search & Rescue: Provide immediate aerial views for safety and response on large, complex sites in emergencies.

- Law Enforcement Support: Monitor high-risk events on site with secure, unmanned help.

-

XRT Battery Swap Dock for DJI Matrice 30 Series:

- A compact and efficient drone box for DJI Matrice 30 and Matrice 30T drones.

- Also features a 3-minute battery swapping time for minimal drone downtime.

- Supports a 15 km operational radius.

- Integrates with XRT Cloud Box M2 for 5G communication, remote control, and real-time mission updates.

- Precision landing with nighttime fill light for safe re-docking.

- Environmental monitoring sensors ensure safe operation in various weather conditions.

- Applications for Construction: Similar to the larger XRT dock, but designed for the more compact Matrice 30 series, making it ideal for smaller sites or where portability is important. It helps manage fire risks, quickly assess remote zones, enhance situational awareness for law enforcement, and scan infrastructure safely.

View Product Details for M30 Station

3. Autel Robotics Drone in a Box Solutions (Offered by XRTech Group)

Autel Robotics offers rugged and versatile drone boxes, suitable for various construction needs, especially with their focus on durability and range.

-

Autel EVO Nest:

- A tough, portable drone in a box solution for the Autel EVO II, EVO II RTK, EVO II Enterprise, and EVO Max Series drones.

- Offers fully automated takeoff, landing, and charging.

- Designed to be weather-resistant.

- Provides an operational range of up to 4.4 miles (about 7 km).

- Includes smart sensors for weather and landing awareness.

- Managed through the Autel Integral Command System for reliable remote operation.

- Benefit for Construction: Its portability and weather resistance make it great for smaller to medium-sized construction sites, or for quick deployment to different parts of a large site. It's especially good for those using Autel's popular EVO series drones.

-

Autel Dragonfish Nest:

- Built specifically for long-range VTOL (Vertical Takeoff and Landing) missions, suitable for the Dragonfish autonomous drone Box series.

- Provides a strong base station for automated launch, land, and recharge.

- Features intelligent power swapping and backup power for continuous 24/7 uptime, essential for very long or ongoing projects.

- Operators use a cloud-based mission platform with predictive analytics and a user-friendly dashboard.

- Benefit for Construction: Ideal for large-scale infrastructure projects (e.g., highways, pipelines, very large developments) that require long-distance flights and continuous monitoring. Its VTOL capability allows it to take off and land like a helicopter but fly like an airplane, covering vast areas efficiently.

Request a Custom Quote for All Drone Solutions!

Real-World Drone in a Box Applications in Construction

The advantages of an autonomous drone Box are best seen in how they are used every day on construction sites. These systems are solving real problems and bringing new levels of efficiency and safety to building projects.

1. Automated Site Monitoring and Progress Tracking

One of the most common uses for a drone in a box solution is to keep a constant eye on the entire construction site.

-

Regular Updates: Drones can be scheduled to fly daily or weekly, capturing images and videos of the site. These regular updates help project managers see the progress of work without having to physically walk the entire site.

-

Spotting Delays Early: By comparing new images to older ones, delays or problems can be spotted quickly. For example, if a certain part of the building is not moving forward as planned, it will be noticed immediately.

-

Ensuring Compliance: Site layouts and safety zones can be checked regularly to make sure they match the plans and safety rules.

2. Safety and Security Inspections

Safety is always a top concern. Drone boxes help make construction sites safer and more secure, especially for dangerous or hard-to-reach areas.

-

Remote Building Inspections: Instead of workers climbing high scaffolding or using lifts, drones can inspect roofs, facades, or structural elements of tall buildings for cracks, damage, or progress. This greatly reduces risks.

-

Perimeter Security: Drones can automatically patrol the edges of a construction site, especially at night or on weekends, to detect unauthorized entry or suspicious activity. This enhances overall site security.

-

Hazard Detection: After an unexpected event like a small fire or structural shift, a drone can be sent in first to assess the situation, identifying dangers before human responders enter.

3. Earthwork Volume Calculation and Material Tracking

Managing large amounts of earth and materials is a big part of construction. Drone in a box solutions can make this much easier and more accurate.

-

Measuring Dirt Piles: Drones can create 3D models of piles of dirt, sand, or gravel. This allows for very accurate calculation of how much material is on site, helping with inventory management and budget control.

-

Tracking Material Movement: The movement of heavy machinery and large amounts of materials can be monitored to ensure efficient placement and usage on site.

-

Excavation Monitoring: The progress of digging and shaping the land (earthwork) can be tracked daily or weekly to ensure it matches the engineering plans.

4. Quality Control and As-Built Documentation

Making sure construction is done right and having a clear record of how everything was built are important.

-

Comparing to Plans: Drone-generated maps and 3D models can be compared directly to the original building plans. This helps spot any mistakes or differences early on, before they become bigger problems.

-

Detailed Records: A complete visual record of the construction process can be created over time. This "as-built" documentation is very valuable for future maintenance, repairs, or legal purposes.

-

Thermal Inspections: Drones with thermal cameras can check for heat leaks in buildings or problems with electrical systems, ensuring quality and energy efficiency.

Advantages of Using an Autonomous Drone Box in Construction (Positive Comments)

Adopting an autonomous drone Box system brings many clear benefits to construction companies. These advantages are why more and more teams are making the switch to these smart tools.

-

Increased Safety: This is a primary benefit. By sending drones to inspect dangerous or hard-to-reach areas, the need for human workers to be in risky situations is greatly reduced. This directly prevents accidents and injuries on site.

-

Improved Efficiency and Speed: Tasks like site surveys, daily progress tracking, and routine inspections can be automated. Drones can fly 24/7 (weather permitting), collecting data much faster than manual methods. This leads to quicker decision-making and keeps projects on schedule.

-

Consistent and Better Data Collection: Automated drone flights ensure that data is collected in the same way every time. This consistency makes it easier to compare information over time, track changes accurately, and create highly precise 2D maps and 3D models. The quality of the data is generally superior to manual methods.

-

Cost Savings in the Long Run: While there is an initial investment in a drone in a box solution, the long-term savings can be significant. This comes from reduced labor costs for routine tasks, preventing costly project delays by spotting problems early, and avoiding expensive equipment rentals (like lifts for inspections).

-

Remote Operation Capabilities: The ability to control and monitor a drone system from a distant office is a huge advantage, especially for companies managing multiple construction sites. This saves travel time and allows for centralized management of all drone operations.

-

Enhanced Security: Drones can provide constant surveillance of a construction site, helping to deter theft and monitor unauthorized access, especially during off-hours. This proactive security layer adds peace of mind.

These benefits make a strong case for why a drone in a box solution is becoming an essential tool for competitive construction firms.

Things to Consider When Choosing a Drone Box for Construction (Critical Comments)

While the benefits of a drone in a box are clear, it is important to also think about some challenges and considerations before making a choice. Being aware of these points helps in planning and setting realistic expectations for your autonomous drone Box.

-

Initial Investment Cost: A high-quality drone in a box solution represents a significant upfront investment. This includes the cost of the specialized drone, the robust docking station, and the software platform. Smaller construction companies might find this initial cost a barrier, requiring careful budget planning.

-

Regulatory Hurdles (Especially BVLOS): Flying drones, especially beyond visual line of sight (BVLOS), often requires special permissions and adherence to strict aviation rules. These regulations can be complex and vary by country or region. Obtaining these permits can take time and effort, which is an important factor to consider before fully deploying an autonomous drone Box for large-scale operations.

-

Maintenance and Support Needs: Like any advanced technology, a drone box system requires regular maintenance to ensure it operates reliably. This includes routine checks of the drone, the box components, and software updates. Reliable technical support from the provider is also crucial in case of issues, as downtime can affect project schedules.

-

Integration with Existing Workflows: While many systems offer compatible file formats, integrating drone-collected data seamlessly into your existing construction management, GIS, or CAD software workflows might require some initial effort or training. It is important to ensure that the data can be used effectively by your team.

-

Environmental Limitations: While modern drone boxes are built to be weather-resistant, extreme weather conditions (like very high winds, heavy rain, or thick fog) can still limit drone operations. Such conditions might require temporary pauses in drone flights, impacting continuous monitoring.

-

Data Security and Privacy Concerns: Drones collect vast amounts of visual data, which might include sensitive information. Ensuring that this data is stored securely, transmitted safely, and used in a way that respects privacy rules is very important. Companies need to have clear policies for data handling.

-

Dependence on Connectivity: For remote operation and cloud-based data management, a strong and consistent internet connection (like 5G) is often needed at the drone box location. In very remote construction sites, establishing reliable connectivity might be a challenge.

By carefully considering these points, construction companies can make informed decisions and prepare for the successful implementation of an autonomous drone Box system.

The Future of Autonomous Drone Box in Construction

The use of drone in a box systems in construction is still growing, and the future holds even more exciting possibilities. As technology gets smarter and easier to use, we can expect these systems to become even more common on construction sites around the world.

-

Smarter AI and Automation: Drones will become even better at making their own decisions, like spotting problems on a site and even reporting them directly to managers without human review. AI will help process data faster and more accurately, identifying complex issues.

-

Advanced Sensors: Future drones will likely carry even more sophisticated sensors that can see through concrete, measure vibrations in structures, or detect very subtle changes in materials. This will open up new uses for an autonomous drone Box.

-

Better Battery Technology: As batteries improve, drones will be able to fly for longer periods, covering even larger areas from a single drone box deployment.

-

Easier Regulations: As the technology becomes more proven and safe, aviation authorities are expected to make it easier to operate drones autonomously and beyond visual line of sight, which will speed up their adoption.

-

Full Integration with Construction Software: The data collected by drone boxes will become even more seamlessly integrated with other construction management software, creating a true "digital twin" of the construction site that updates automatically.

The future of construction is looking more automated, safer, and data-driven, with the drone in a box solution playing a central role in this exciting transformation.

Final Thoughts: The Power of the Drone in a Box

The drone in a box solution is no longer just a futuristic idea; it is a real tool that is bringing immense value to the construction industry today in 2026. By offering automated site monitoring, improved safety, more efficient data collection, and significant cost savings, these drone boxes are helping companies build smarter and faster.

Choosing the best drone in a box involves looking at its durability, range, drone compatibility, battery management, accuracy, data handling, and overall autonomy. XRTech Group is proud to offer a range of leading solutions, including the advanced DJI Dock series and our own innovative XRT Battery Swap Docks, specifically designed to meet the rigorous demands of construction projects. These systems are built to ensure your construction operations are as precise and productive as possible.

As construction continues to evolve, the autonomous drone Box will play an increasingly central role. It empowers teams to achieve new levels of efficiency and safety, allowing them to focus on the core work of building while the drones handle the routine, repetitive tasks. We believe that by understanding and adopting these powerful technologies, construction companies can gain a significant edge in today's competitive market.

Ready to bring an autonomous drone Box to your construction site?

Request a Custom Quote Today!

Discover how XRTech Group can help your project with the best drone in a box solution.