How Do Almonds Grow? Complete Farming Guide from Planting to Harvest

Growing almonds is a structured agricultural process that moves from orchard planning to nut harvest and post-season care. Farmers must

The mining industry is undergoing a digital transformation where mining satellite imagery-based intelligence is replacing traditional, labor-intensive field methods. By utilizing high-resolution satellite imagery, AI-powered analytics, and specialized sensors, companies can now monitor the progress of mining operations throughout the entire project lifecycle—from the first signs of mineralization to post-closure restoration.

Talk to XRTech About Your Project

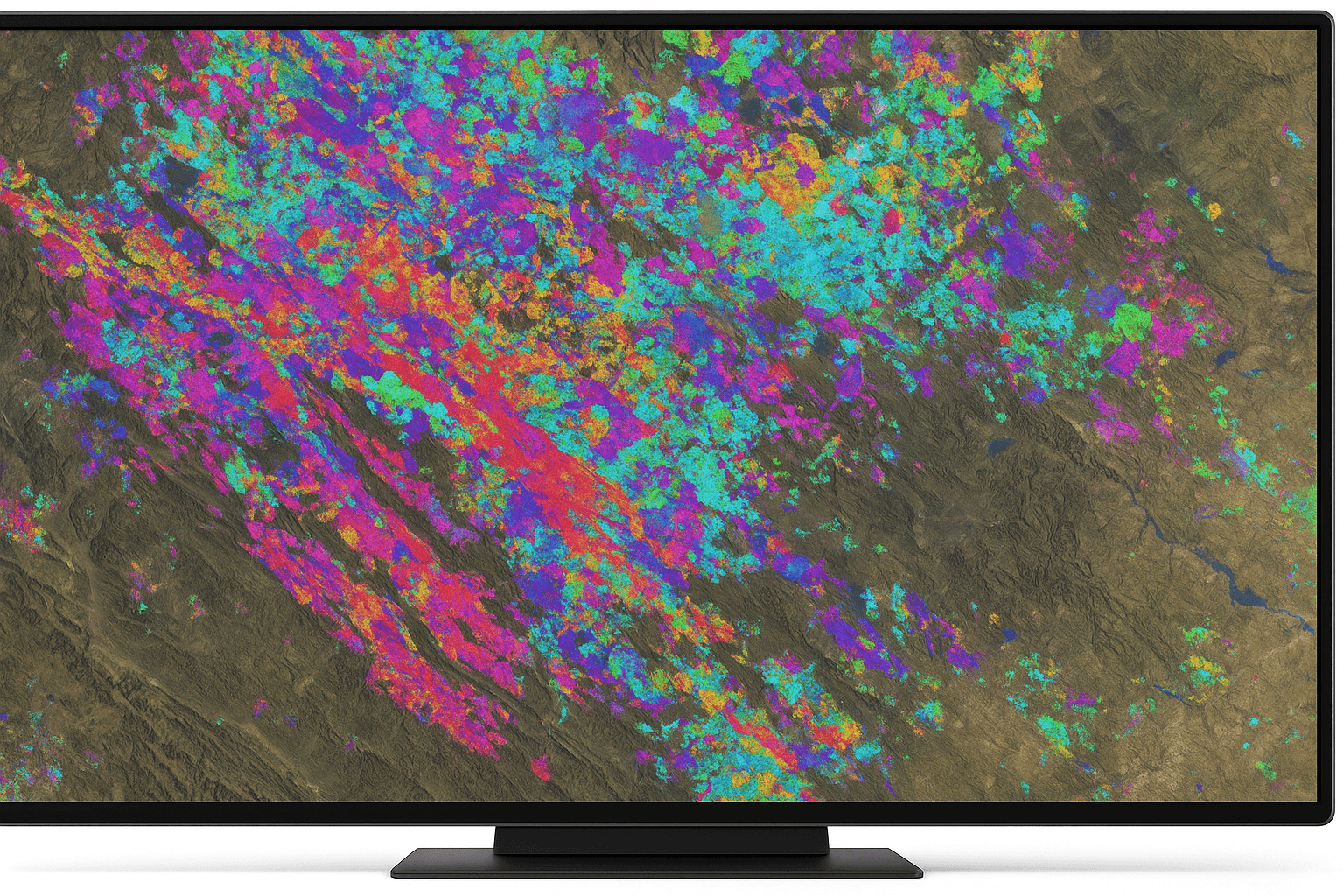

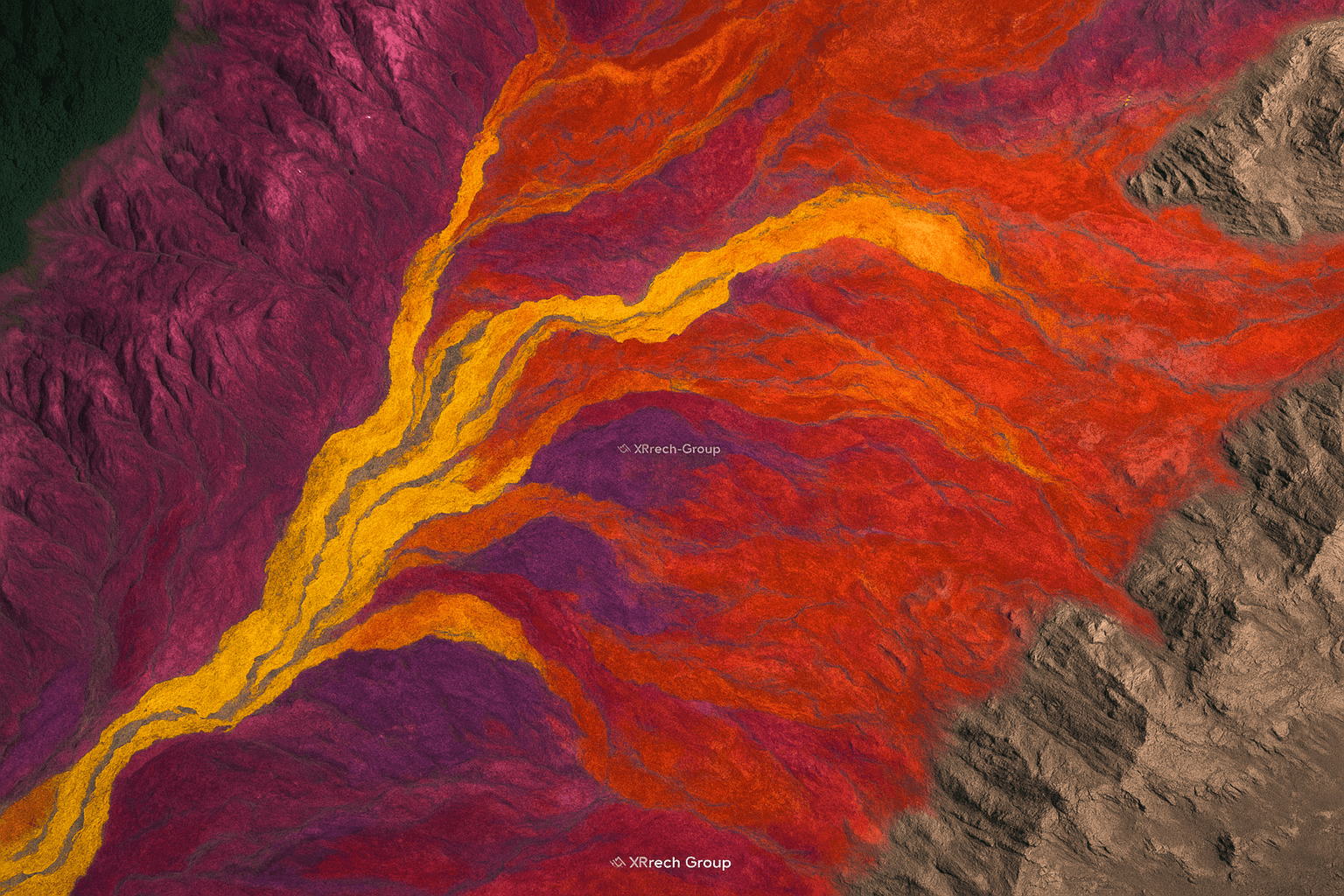

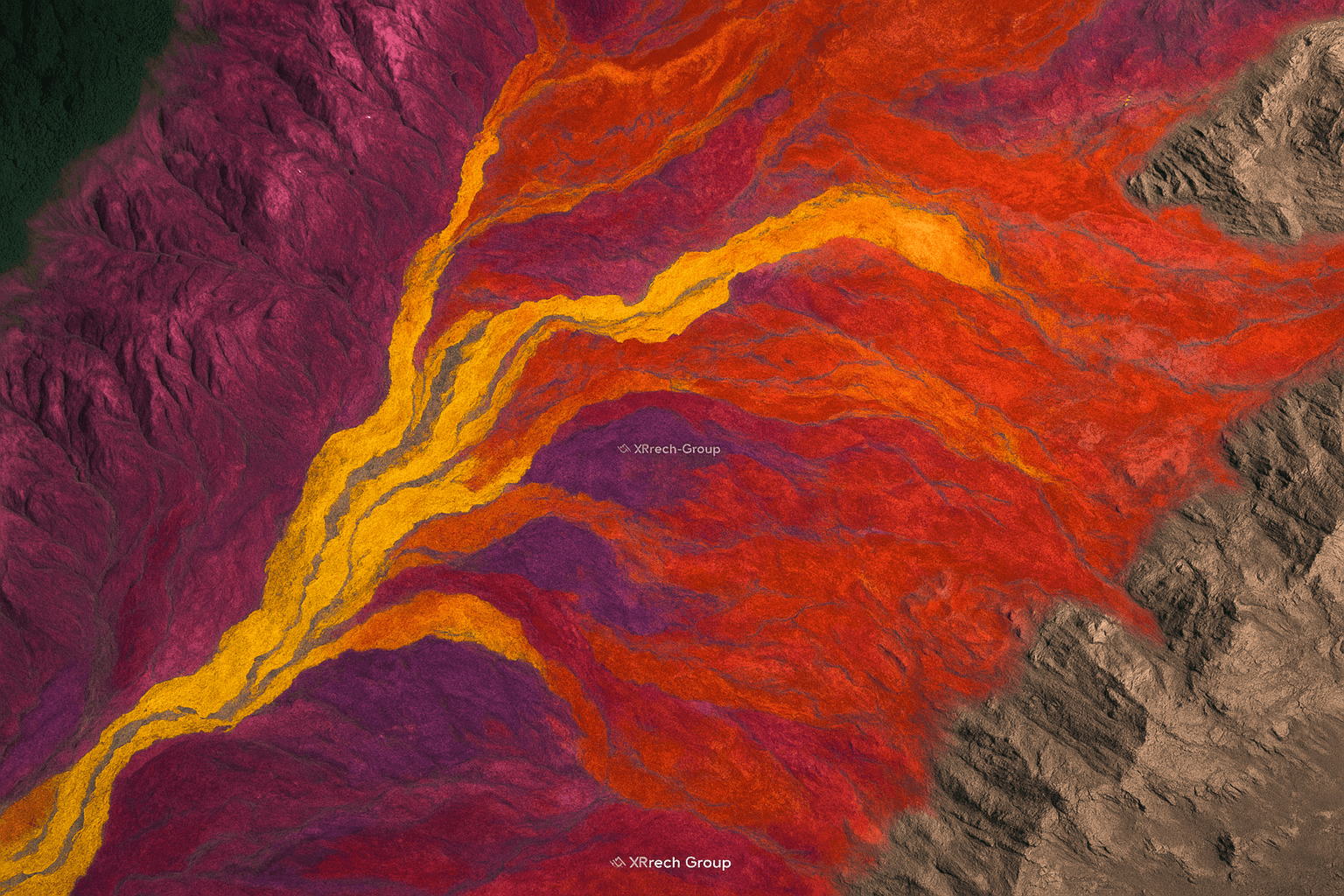

In the early stages, the challenge lies in pinpointing deposits across vast, remote terrains. Specialized satellite-based sensors capture wavelengths of light beyond human vision, such as the short-wave infrared (SWIR) spectrum, which are essential for spectral fingerprinting the Earth’s surface.

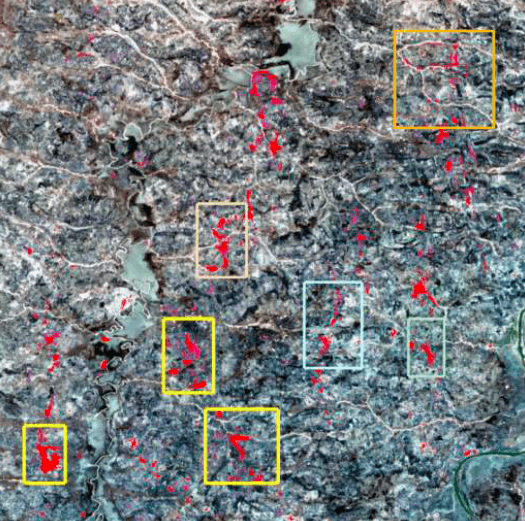

Notable satellites, including the GF-5B and ZY-1 02D, have transformed exploration by detecting specific SWIR wavelengths that identify alteration minerals. These minerals, such as sericite, kaolinite, illite, and iron oxides, act as indicators for hydrothermal gold and base-metal systems. This remote detection allows exploration teams to narrow down vast regions to high-probability target zones before deploying costly ground teams.

Geologists use high-resolution imagery and Digital Elevation Models (DEMs) to identify critical lineaments, such as faults, fractures, and shear zones. Unlike ground-level surveys, satellite-based structural mapping provides a regional perspective that reveals the tectonic frameworks governing mineral concentration.

Once targets are identified, satellite data plays a key role in early exploration planning. Detailed terrain analysis helps teams design optimal access tracks and roads to remote drill sites. This logistical capacity significantly reduces the time and cost associated with establishing exploration operations in challenging environments.

Furthermore, 3D geological mapping using Digital Orthophoto Maps (DOM) and DEM datasets provides a multi-dimensional view of the landscape, allowing engineers to estimate overburden and evaluate site feasibility before breaking ground.

As a project moves into extraction, satellite intelligence shifts toward operational efficiency and infrastructure safety.

The mining lifecycle does not end when extraction stops. Satellite imagery for mine site rehabilitation and closure ensures that companies meet environmental regulations and restore the land responsibly.

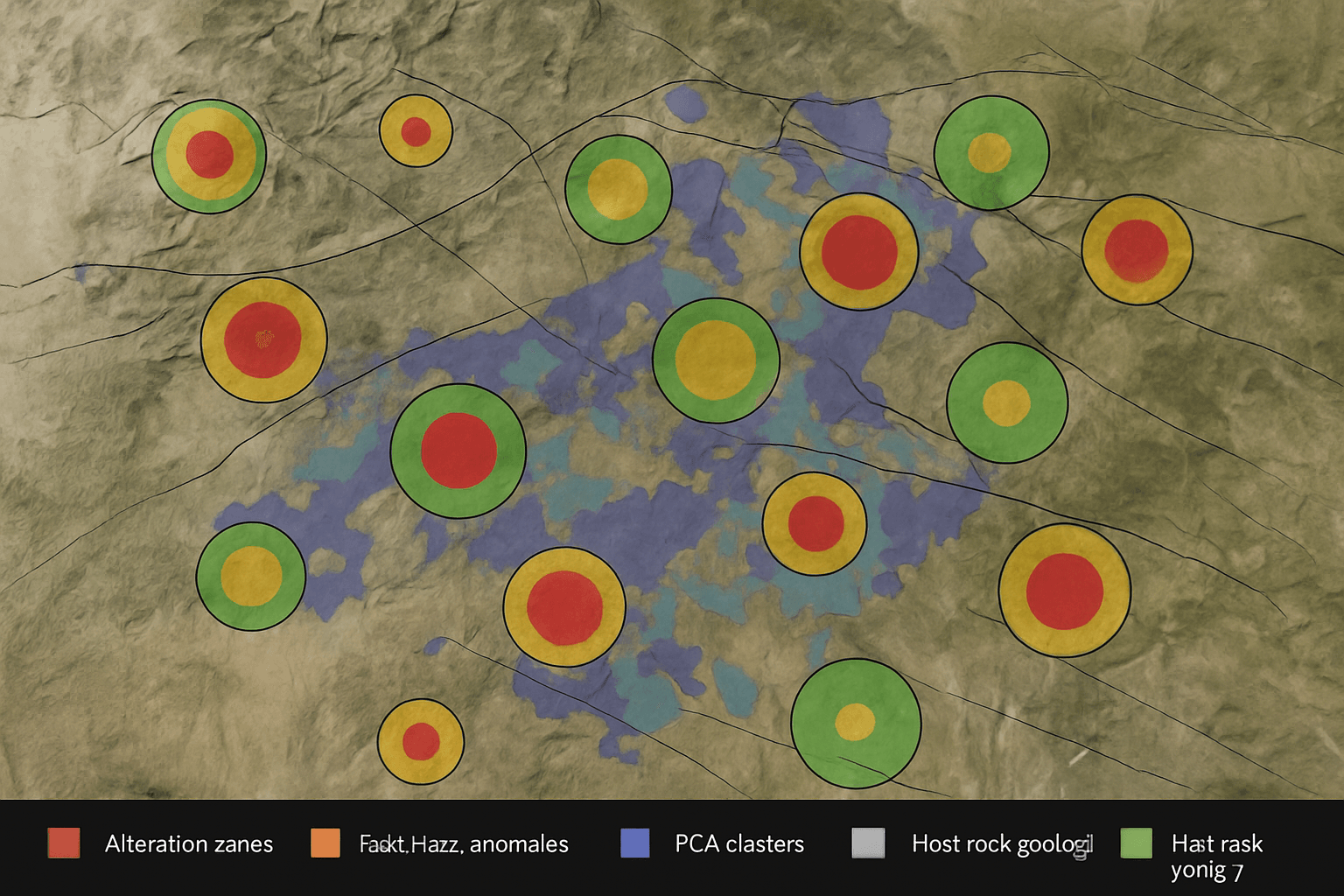

XRTech’s Khaza’in methodology provides a modern, cost-efficient path to mineral targeting using proprietary Deep Learning Algorithms:

By integrating this end-to-end process, XRTech Group slashes exploration timelines from years to days, giving landowners and partners a decisive competitive edge in uncovering the Earth’s hidden wealth.

XRTech Group provides a comprehensive satellite-driven solution for the entire mining lifecycle, from early-stage discovery to post-closure restoration. By utilizing high-resolution imagery and AI-powered analytics, the company helps operators reduce risks, ensure regulatory compliance, and optimize resource management from space.

XRTech’s Khaza’in intelligence platform has demonstrated world-class results across several high-value mineral provinces, drastically reducing traditional exploration timelines.

| Region | Case Study Highlight | Reported Timeline |

|---|---|---|

| Tanzania | Rapid identification of gold mineralization in the Lake Victoria Gold Belt, helping flag viable zones near artisanal workings. | Delivered in <20 days. |

| Chile | Mapped copper and alteration signatures in the Andean Copper Region, saving months of fieldwork and allowing partners to reprioritize drill schedules. | Saved months of field time. |

| Mauritania | Mapped 10 priority gold zones adjacent to one of Africa’s largest mines (Tasiast Mine Region) with a probability of up to 21.69%. | Rapid deployment. |

| West Africa | Analyzed hundreds of square kilometers of remote terrain to generate a ranked list of gold exploration targets for a leading mining company. | Rapid Data Delivery. |

The platform is engineered for speed, ensuring that critical data is available to decision-makers in days rather than months.

Using satellite intelligence for mining is like having a time-traveling telescope; it allows you to look back through decades of historical archives to understand a land’s past while simultaneously providing a real-time vision that detects hidden wealth buried deep beneath the surface, far beyond what the naked eye can see.

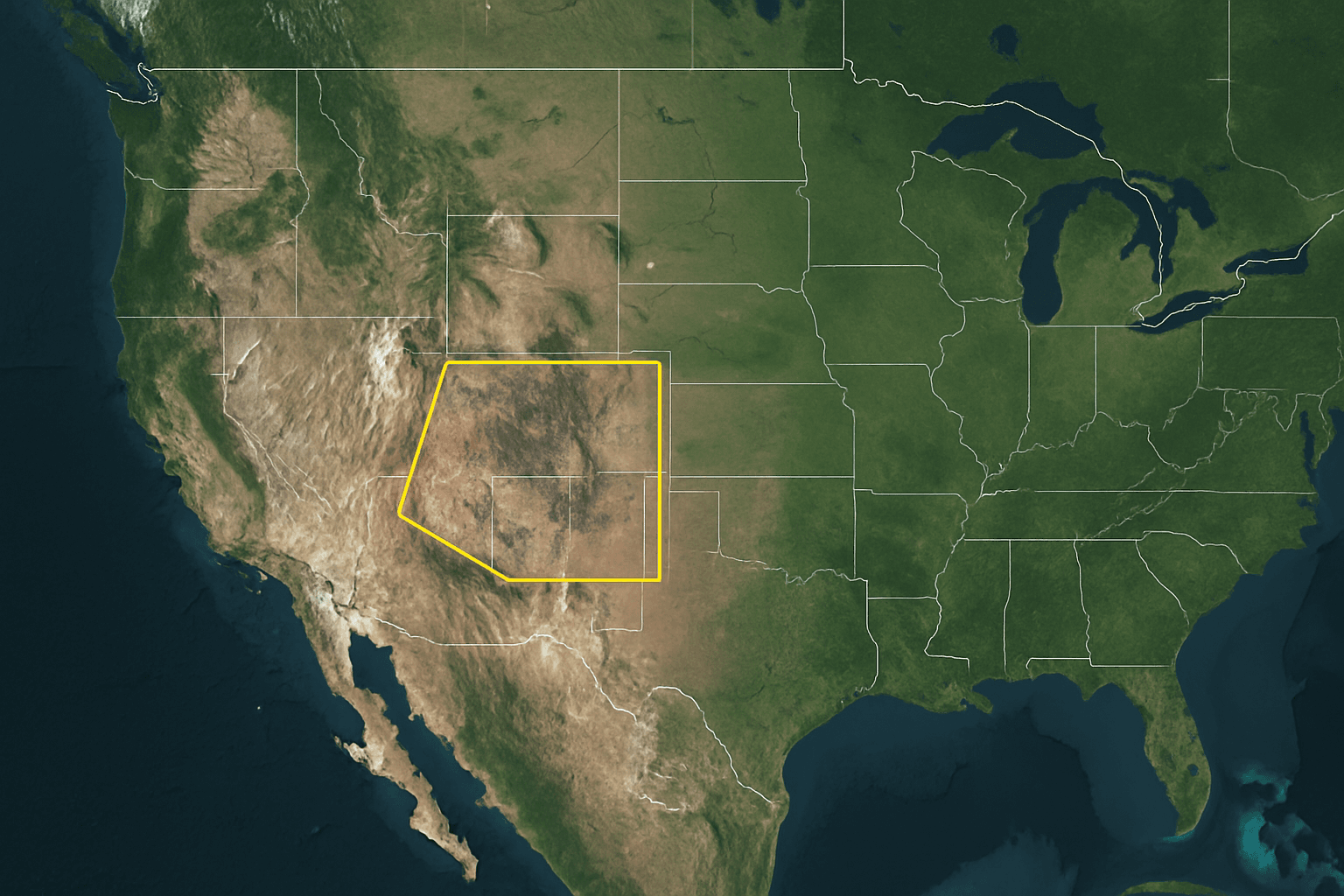

XRTech Group’s application of the mining lifecycle in Mauritania specifically targets the Tasiast Mine Region, situated within the Reguibat Shield. This area is characterized by Precambrian rocks, which provide an ideal geological environment for hosting hydrothermal gold deposits. The sources outline a comprehensive, multi-stage satellite-driven approach for this region:

In the initial phase, XRTech analyzed several hundred square kilometers of remote terrain to identify high-potential deposits. The methodology involves Remote Sensing Data Fusion, where multispectral and interferometric data are integrated to map structural features like shear zones and faults that are critical for mineral concentration. Using proprietary Deep Learning algorithms, the analysis identified 10 priority gold zones. In this case study, the top target showed a calculated gold probability of 21.69%, providing a significant advantage for landowners negotiating exploration rights.

Once targets are identified, the sources explain that Digital Elevation Models (DEM) and surface analysis are used to evaluate the terrain. This intelligence helps exploration teams identify optimal tracks and roads to access drill sites in remote areas, which is vital for reducing the time and cost of establishing operations in the West African desert. These models also allow engineers to estimate overburden and detect potential geohazards before physical work begins.

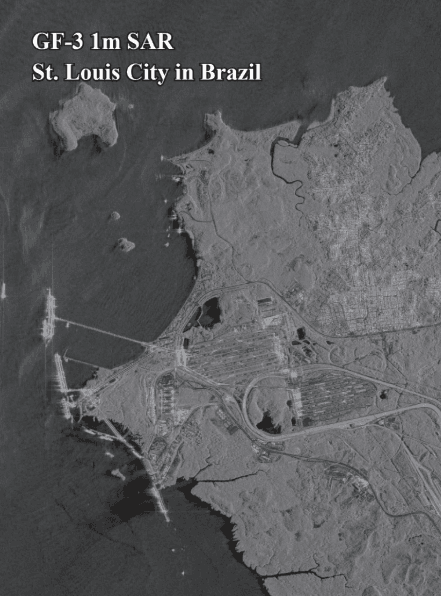

During active mining, the focus shifts to operational efficiency and risk mitigation. Routine high-resolution imagery is used to track land disturbance and pit development in real-time. Crucially, XRTech employs InSAR (Interferometric Synthetic Aperture Radar) technology to monitor the structural integrity of critical infrastructure, such as tailings dams and pipelines. This technology detects millimeter-level deformation, allowing for the early identification of structural risks to prevent environmental disasters.

The lifecycle concludes with post-closure remediation and environmental audits. Satellite imagery provides verifiable documentation of land restoration and vegetation health to ensure compliance with environmental regulations. Hyperspectral sensors are used to monitor water quality parameters (such as pH, heavy metals, and turbidity) and detect potential contamination sources from legacy waste or tailings dams.

In summary, for Mauritania, using satellite intelligence is like having a digital surveyor that never sleeps; it monitors the vast, shifting sands of the Reguibat Shield to pinpoint hidden wealth while ensuring the structural safety of the mines that extract it.

XRTech Group delivers a complete satellite-driven intelligence workflow across exploration, development, operations, and closure—helping mining stakeholders move faster, reduce risk, and make confident decisions with verifiable data from space.

If you want to reduce field costs, shorten timelines, and prioritize only the highest-confidence targets, XRTech’s Khaza’in platform and satellite analytics can provide the decisive edge.

Satellite intelligence has fundamentally redefined how mining projects are discovered, developed, operated, and closed. What was once a process driven by fragmented field surveys and long timelines is now an integrated, data-driven workflow powered by high-resolution imagery, AI analytics, hyperspectral sensing, and InSAR monitoring. From identifying alteration minerals in remote terrains to ensuring the long-term safety and environmental compliance of closed mine sites, satellite data delivers continuous, objective insight at every stage of the mining lifecycle.

XRTech Group brings this transformation together through its end-to-end, satellite-driven approach. By combining a global constellation of satellites with proprietary AI and the Khaza’in intelligence process, XRTech enables mining stakeholders to move faster, reduce uncertainty, lower operational costs, and make confident decisions backed by verifiable data from space. In an industry where time, accuracy, and risk define success, satellite intelligence is no longer an advantage—it is the foundation of modern mining.

1. How is satellite imagery used across the entire mining lifecycle?

Satellite imagery supports every stage of mining, including early mineral exploration, site feasibility and development, active operations monitoring, infrastructure safety, and post-closure environmental rehabilitation. It provides continuous, large-scale, and objective data from space.

2. What types of satellite data are most important for mineral exploration?

Hyperspectral, multispectral, and Short-Wave Infrared (SWIR) imagery are critical for identifying alteration minerals such as sericite, kaolinite, illite, and iron oxides, which indicate hydrothermal mineral systems.

3. How does satellite imagery reduce exploration costs?

By narrowing vast regions into high-probability target zones before fieldwork begins, satellite intelligence minimizes unnecessary drilling, reduces large-scale ground surveys, and shortens exploration timelines from years to days.

4. What is InSAR and why is it important for mining operations?

InSAR (Interferometric Synthetic Aperture Radar) detects millimeter-level ground deformation. It is used to monitor tailings dams, pipelines, slopes, and other critical infrastructure to identify early signs of instability and prevent failures.

5. Can satellite imagery monitor active mining operations in real time?

Yes. High-resolution satellite imagery enables routine monitoring of pit expansion, land disturbance, stockpile volumes, and operational progress, providing a consistent audit trail for operators and stakeholders.

6. How does XRTech’s Khaza’in process improve mineral targeting?

The Khaza’in process integrates AI-driven hyperspectral analysis, deep learning classification, and ground-truth validation to generate mineral probability maps, GPS-based targets, and confidence layers for drilling decisions.

7. Is satellite imagery effective for remote or inaccessible mining regions?

Absolutely. Satellite intelligence is especially valuable in remote deserts, dense forests, and politically or logistically challenging regions where traditional field surveys are costly or impractical.

8. How is satellite data used for mine rehabilitation and closure?

Satellite imagery tracks vegetation regrowth, land degradation, deforestation, and water quality parameters such as pH, turbidity, and heavy metals to ensure environmental restoration and regulatory compliance after mine closure.

9. How fast can XRTech deliver satellite mining intelligence?

For small Areas of Interest (under 100 km²), XRTech’s Khaza’in platform delivers results within 2–3 days. Standard imagery is typically delivered within 4–7 days, with urgent access possible within 24 hours.

10. Why is satellite intelligence becoming essential for modern mining companies?

Satellite intelligence provides faster decision-making, reduced risk, lower operational costs, and continuous monitoring across the entire mining lifecycle. It enables data-driven strategies that traditional ground-based methods cannot match.

Get access to the best satellite data for Mining with sub-meter resolution & DEM models at industry-leading prices

Growing almonds is a structured agricultural process that moves from orchard planning to nut harvest and post-season care. Farmers must

Rapid Detection and Response to Marine Oil Spills XRTech Group enables governments, coast guards, and energy operators to rapidly detect