Tailings Dam Monitoring: How Advanced Satellite Intelligence Is Transforming Tailings Dam Safety

Tailings dams are among the most critical—and high-risk—structures in the global mining industry. Built to store the by-products of mineral processing, these facilities must remain stable not for years, but for decades, sometimes centuries. When a tailings dam fails, the consequences extend far beyond a mine boundary: communities are devastated, ecosystems collapse, and economic damage spreads across entire regions.

Yet despite increasing regulatory standards and the Global Industry Standard on Tailings Management (GISTM), tailings dam failures continue to occur worldwide. The challenge is not simply engineering—it is persistent monitoring.

Today, tailings dam monitoring is evolving from periodic ground inspections to continuous, satellite-based geospatial intelligence. XRTech Group provides a comprehensive ecosystem for tailings dam monitoring that replaces slow, manual inspection cycles with persistent, millimeter-level orbital oversight powered by advanced SAR, InSAR, hyperspectral imaging, and AI-driven analytics.

This article explores:

What tailings dams are and why they fail

Why traditional monitoring methods are no longer enough

How satellite InSAR delivers millimeter-level deformation detection

How hyperspectral imaging strengthens environmental compliance

Why integrated AI-based early warning systems are critical

How XRTech’s orbital ecosystem provides 24/7, all-weather monitoring

Understanding Tailings Dams: A High-Risk Engineering Reality

Tailings are the fine-grained waste materials left after extracting valuable minerals from ore. Often stored as a slurry composed of water, crushed rock, chemical residues, and fine sediments, tailings must be contained within engineered storage facilities known as Tailings Storage Facilities (TSFs).

Tailings dams are typically constructed using one of three methods:

Upstream

Downstream

Centreline

Each design responds to site-specific environmental, seismic, and hydrological conditions. However, regardless of design, tailings dams share a fundamental characteristic: they often store unstable, saturated material behind embankments that may themselves be constructed from tailings.

Unlike conventional water-retention dams, tailings dams are raised incrementally as production increases. This sequential raising process introduces structural complexity, drainage challenges, and long-term stability risks.

When failures occur, they are often catastrophic.

Historical records show more than 200 documented failures in the past century. Unlike conventional dams, tailings dam failure rates are significantly higher. The reasons are complex and interrelated.

Why Tailings Dams Fail

Tailings dam failures rarely occur without warning. They are typically the result of progressive structural degradation combined with insufficient monitoring.

Key causes include:

Static Liquefaction

Loose, saturated tailings can suddenly lose shear strength, causing rapid structural collapse.

Seepage and Pore Pressure

Water slowly permeating through embankments can erode foundation material. Increased pore pressure reduces slope stability and may trigger failure.

Overtopping

Excess rainfall or water mismanagement can cause tailings levels to exceed crest elevation.

Seismic Activity

Even moderate earthquakes can destabilize improperly consolidated tailings.

Sequential Raising Without Adequate Consolidation

Upstream dams especially require careful timing between raises to ensure consolidation. Inattention increases risk.

Long-Term Neglect

Inactive dams often receive less monitoring, despite the fact that tailings must remain stable for thousands of years.

The core issue is that most traditional monitoring systems detect problems after visible movement occurs. By the time cracks or slope deformation are seen on-site, instability may already be advanced.

Modern tailings dam monitoring must detect changes before they become visible.

The Evolution of Tailings Dam Monitoring

Historically, monitoring relied on:

Piezometers to measure pore pressure

Inclinometers to track internal deformation

Total earth pressure cells

Seismic sensors

Ground-based radar systems

These technologies remain valuable, but they have limitations:

Limited spatial coverage

Expensive installation and maintenance

Vulnerability to environmental damage

Dependence on physical access

Human data collection delays

As tailings dams grow larger and more complex, operators require continuous, wide-area, high-precision monitoring. This is where satellite-based InSAR changes the paradigm.

Structural Integrity Monitoring via InSAR

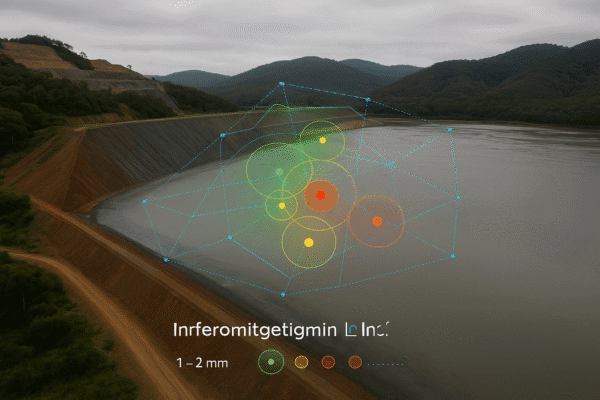

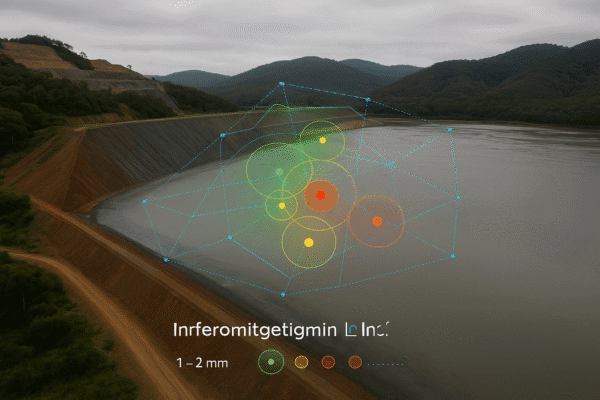

The cornerstone of XRTech Group’s tailings dam monitoring ecosystem is Interferometric Synthetic Aperture Radar (InSAR).

InSAR compares radar signals collected from multiple satellite passes over the same location. By analyzing phase differences, it detects surface displacement at extremely fine scales.

Millimeter-Level Precision

XRTech’s InSAR systems detect movement as small as 1–2 millimeters across dam walls, slopes, and surrounding terrain.

This level of precision allows operators to identify:

These subtle signals often precede catastrophic failure.

Unlike visual inspections, InSAR identifies movement trends over time, not just isolated snapshots.

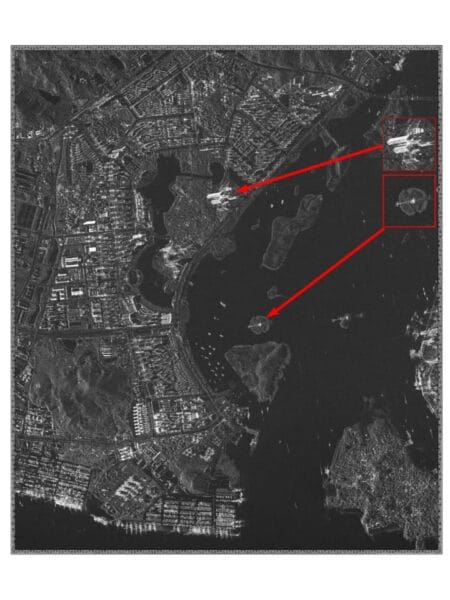

Dedicated Deformation Monitoring Satellites

XRTech leverages the LT-1 L-band SAR constellation, specifically designed for surface deformation interferometry.

L-band radar provides improved penetration into soil and vegetation compared to shorter wavelengths, enhancing measurement reliability over tailings surfaces.

Because satellites revisit regularly, deformation histories can be constructed, allowing engineers to evaluate acceleration patterns and intervene early.

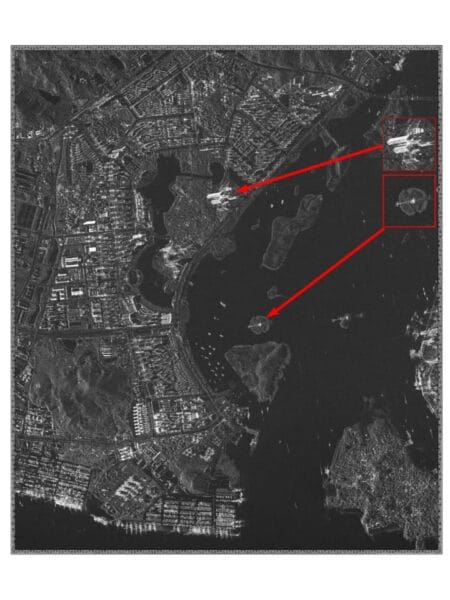

All-Weather, 24/7 Monitoring: The SAR Advantage

One of the most critical weaknesses of optical satellite systems is their dependence on clear weather and daylight.

Tailings dams are often located in:

XRTech’s SAR fleet acts as an unblinking eye.

Cloud and Smoke Penetration

SAR sensors operate in microwave frequencies that penetrate clouds, fog, and smoke.

Day and Night Capability

SAR is an active sensor—it provides its own illumination. Monitoring continues regardless of darkness.

This means tailings dam monitoring does not pause during monsoon seasons or extreme weather events—the very conditions that increase failure risk.

Persistent oversight dramatically reduces blind spots in risk management.

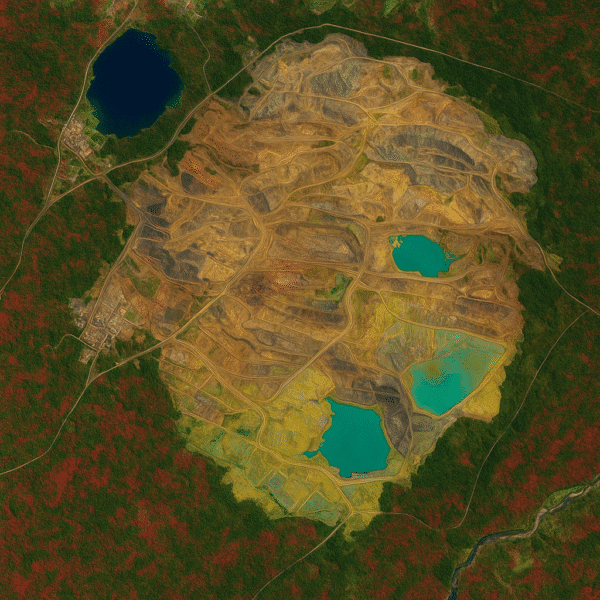

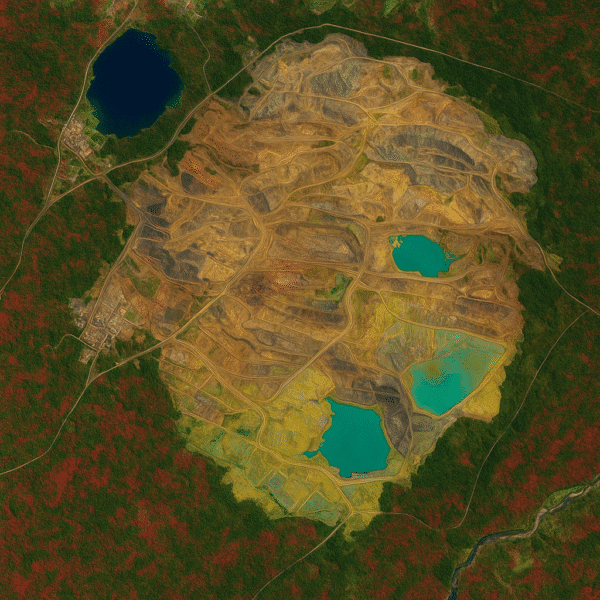

Environmental Impact and Contamination Monitoring

Structural stability is only one part of tailings dam safety. Environmental contamination risk must also be managed continuously.

Tailings reservoirs can release contaminants through:

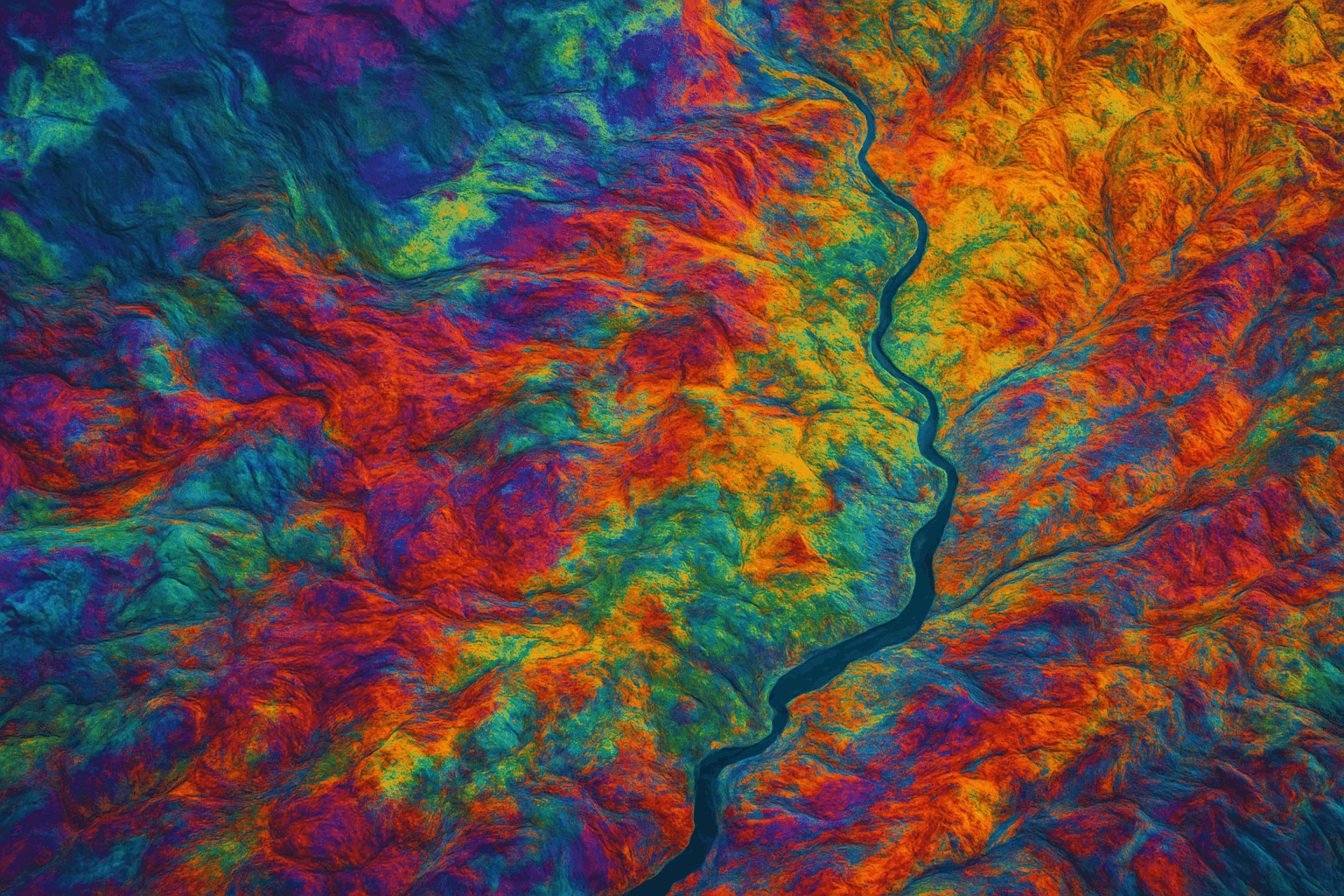

XRTech integrates hyperspectral satellite imaging to monitor environmental conditions around tailings facilities.

Water Quality Analysis

Hyperspectral data enables detection of:

Unlike ground sampling, which is periodic and localized, hyperspectral imaging surveys the entire reservoir and surrounding ecosystem.

Pollution Prevention

By identifying anomalous spectral signatures downstream from tailings facilities, operators can detect potential leakage before contamination spreads widely.

Historical Change Analysis

XRTech maintains archives dating back to 1999. By comparing current satellite data with historical imagery, mining companies can:

This time-depth intelligence transforms environmental monitoring from reactive compliance to strategic oversight.

Integrated AI for Early Warning and Disaster Prevention

Data alone does not prevent failure. Interpretation speed matters.

XRTech integrates satellite monitoring with AI-powered analytics platforms that automatically identify:

These systems generate automated alerts when predefined risk thresholds are exceeded.

Instead of waiting for periodic engineering reviews, operators receive continuous digital risk intelligence.

Emergency Response Capability

In the event of an incident or sudden geohazard, XRTech can deliver emergency satellite imaging and actionable analysis within as fast as 24 hours.

This rapid response capability supports:

Speed matters when downstream communities are at risk.

Meeting Global Tailings Standards

The Global Industry Standard on Tailings Management emphasizes:

Continuous monitoring

Transparency

Risk reduction

Zero harm objectives

To achieve zero harm, monitoring systems must integrate surface and sub-surface intelligence.

XRTech’s ecosystem supports:

Remote satellite InSAR

Hyperspectral environmental analysis

Historical archive comparison

AI-based anomaly detection

This integrated approach aligns with evolving regulatory frameworks while reducing manual inspection dependency.

Why Satellite-Based Tailings Dam Monitoring Is Now Essential

Tailings dams are not temporary structures. Many must remain stable for thousands of years.

Climate change introduces new stressors:

Manual inspections and isolated sensors cannot provide full-site awareness at required scale.

Satellite-based InSAR provides:

Wide-area coverage

Millimeter-level accuracy

Continuous revisit

No on-site installation requirement

Historical deformation trend analysis

When combined with hyperspectral environmental monitoring, operators gain both structural and ecological intelligence.

The XRTech Advantage in Tailings Dam Monitoring

XRTech Group offers a comprehensive monitoring ecosystem rather than a single instrument.

This includes:

LT-1 L-band SAR for deformation monitoring

Multi-satellite constellation for global coverage

Hyperspectral imaging for contamination detection

Historical archive access since 1999

AI-driven anomaly detection systems

24/7 all-weather capability

Emergency imaging within 24 hours

Unlike systems that rely solely on ground-based radar or isolated sensors, XRTech provides orbital oversight that continuously scans large tailings facilities and surrounding terrain.

This transforms monitoring from episodic to persistent.

From reactive to predictive.

From manual to intelligent.

What Happens If a Tailings Dam Fails?

When a tailings dam fails, the consequences are immediate, far-reaching, and often irreversible. Unlike conventional water dams, tailings dams contain a mixture of fine waste materials, water, and chemical residues from mineral processing. When structural integrity is lost, millions of cubic meters of toxic slurry can be released within minutes, overwhelming everything in its path.

Immediate Human and Environmental Impact

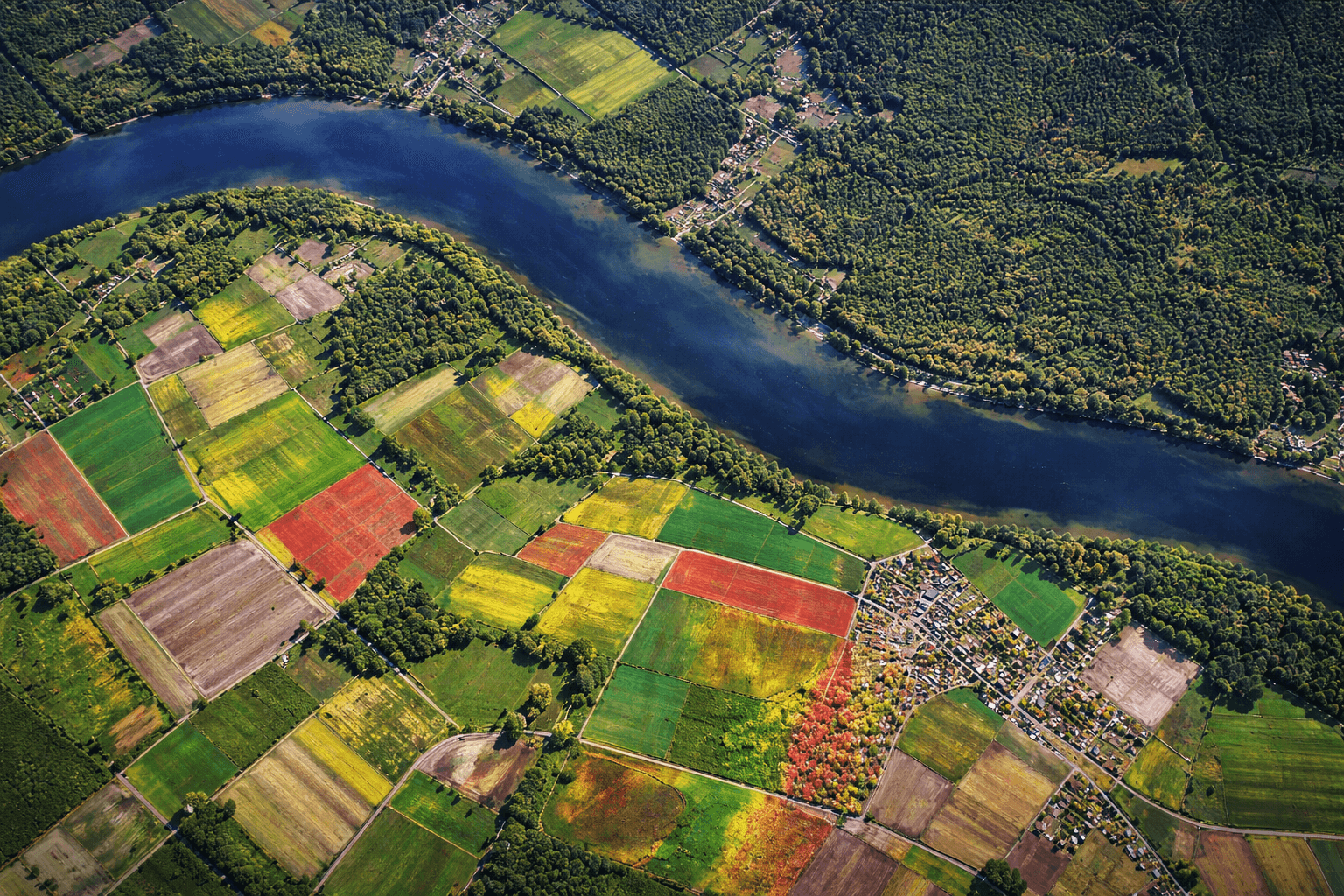

A tailings dam failure can generate a fast-moving wave of mud, water, and mine waste that travels several kilometers downstream. Communities located near mining operations are often the first to be affected. Infrastructure is destroyed, agricultural land is buried, and access to clean drinking water becomes compromised.

The environmental damage extends well beyond the initial collapse. Tailings often contain heavy metals, sulfides, and chemical processing agents. Once released, these contaminants infiltrate rivers, groundwater systems, and soil layers, causing long-term ecosystem disruption. Aquatic life suffers from oxygen depletion, sediment overload, and chemical toxicity. Recovery can take decades, and in some cases, full restoration is impossible.

Economic and Operational Consequences

For mining operators, the financial consequences are severe. A single tailings dam failure can result in:

Multi-billion-dollar cleanup costs

Regulatory fines and legal liabilities

Operational shutdowns

License revocation

Loss of investor confidence

Insurance premiums increase, shareholder trust declines, and project financing becomes more difficult. Beyond the immediate disaster response, companies may face years of litigation and reputational damage.

Long-Term Environmental Liability

Tailings dams are expected to remain stable for extremely long periods—sometimes thousands of years. When a failure occurs, contamination may persist across watersheds and agricultural regions long after mining operations cease.

Heavy metals can bioaccumulate in food chains. Soil degradation can reduce land productivity for generations. Water systems may require expensive treatment programs indefinitely. The long-term environmental liability often exceeds the original economic value of the mine.

Regulatory and Governance Fallout

Following a tailings dam failure, governments frequently tighten regulations, increase compliance requirements, and mandate stricter monitoring standards. Operators may be required to redesign facilities, implement new safety systems, or decommission high-risk structures.

International frameworks such as the Global Industry Standard on Tailings Management emphasize continuous monitoring, independent oversight, and risk transparency precisely because of the catastrophic potential of failures.

Why Early Detection Matters

Tailings dam failures are rarely instantaneous events without warning. Most are preceded by measurable indicators:

Without advanced tailings dam monitoring systems such as InSAR-based deformation tracking and satellite environmental surveillance, these early signals can go unnoticed.

Detecting millimeter-level movement before visible cracks form can mean the difference between controlled remediation and catastrophic collapse.

Are There Any Alternatives to Tailings Dams?

Tailings dams have long been the dominant method for storing mine waste, but they are not the only option. As environmental expectations rise and regulatory scrutiny increases, mining companies are actively exploring safer, lower-risk alternatives to conventional wet tailings storage facilities (TSFs). While no solution is universally applicable, several technologies and design approaches are reducing dependence on large slurry-filled embankments.

Understanding these alternatives is essential for both risk reduction and long-term sustainability.

Dry Stacking (Filtered Tailings)

One of the most widely discussed alternatives is dry stacking, also known as filtered tailings.

In this approach, water is removed from tailings using filtration systems before disposal. The resulting material resembles damp soil rather than slurry. It is then compacted and stacked in layers, eliminating the need for large water-retaining embankments.

Because there is significantly less water involved, the risk of catastrophic liquefaction or overtopping is reduced. Dry stacking also allows better water recovery, which is valuable in water-scarce regions.

However, dry stacking comes with trade-offs:

Higher upfront capital cost

Increased energy consumption for filtration

Not always feasible for very large-scale operations

Requires specific climatic and geotechnical conditions

While safer in many contexts, dry stacking does not eliminate the need for monitoring. Stability, drainage, and erosion must still be managed continuously.

Thickened or Paste Tailings

Thickened tailings represent a middle ground between conventional slurry dams and fully dry stacking. In this method, tailings are dewatered to a higher density before being deposited.

Paste tailings flow slowly and consolidate faster, reducing free water accumulation and lowering the risk of static liquefaction. This approach can reduce dam height requirements and improve geotechnical stability.

However, thickened tailings facilities still require containment structures and ongoing monitoring. They are not inherently failure-proof.

In-Pit Tailings Disposal

Some mining operations use exhausted open pits as containment areas for tailings. By placing waste material within existing mine voids, operators reduce the need for new embankments.

In-pit storage can reduce environmental footprint and structural exposure, but it is only feasible where geological and hydrogeological conditions allow. Groundwater contamination risk must still be carefully managed.

Underground Backfilling

In underground mining, tailings can sometimes be mixed with binders and used as backfill material to stabilize mined-out cavities.

This reduces surface storage requirements and improves underground structural integrity. However, it is limited to specific mining methods and does not eliminate surface disposal entirely.

Water Cover and Subaqueous Disposal

In some regions, tailings are deposited under a water cover to reduce oxidation and acid generation. While this method can minimize certain environmental reactions, it still requires careful dam design and long-term water management.

Do Alternatives Eliminate Risk?

No alternative completely removes risk.

Every tailings management strategy—whether conventional dam, dry stack, or in-pit storage—requires continuous structural and environmental monitoring. Climate variability, seismic activity, and long-term geotechnical behavior introduce uncertainties that cannot be engineered away entirely.

The real shift in modern tailings management is not just about alternative storage methods. It is about integrating continuous monitoring technologies that provide early warning of instability.

Tailing Dam Monitoring Remains Essential — Regardless of Design

Even alternative tailings systems must be monitored for:

Satellite-based InSAR, SAR, and hyperspectral imaging play a critical role in overseeing both conventional and alternative facilities.

For example:

Dry stack facilities can still experience slope movement.

In-pit storage requires groundwater monitoring.

Thickened tailings may still undergo consolidation settlement.

Persistent orbital monitoring ensures early detection of movement trends before they escalate into structural hazards.

The Future of Tailings Management

The industry is gradually shifting toward lower-risk designs, improved filtration technologies, and stricter global standards such as the Global Industry Standard on Tailings Management.

However, structural design alone cannot guarantee safety over decades or centuries.

True resilience comes from combining:

Improved engineering design

Regulatory oversight

Continuous satellite monitoring

AI-driven anomaly detection

Historical data analysis

Tailings dam alternatives reduce risk, but monitoring eliminates blind spots.

Blog Summary

Tailings Dam Monitoring is critical because tailings dams store mining waste slurry that can cause catastrophic environmental and human damage if structural failure occurs.

A Tailings Dam can fail due to seepage, static liquefaction, overtopping, seismic activity, poor drainage, or long-term neglect—most failures are preceded by measurable warning signs.

Traditional monitoring methods such as piezometers and ground inspections are limited in coverage, while satellite-based InSAR monitoring provides wide-area, continuous deformation tracking.

XRTech Group uses Interferometric Synthetic Aperture Radar (InSAR) to detect surface displacement as small as 1–2 mm, enabling early warning before visible cracks or collapse occur.

The LT-1 L-band SAR constellation delivers millimeter-level deformation monitoring with all-weather and day-night capability, ensuring uninterrupted tailings dam surveillance.

Unlike optical systems, SAR-based tailings dam monitoring penetrates clouds, rain, fog, and smoke, making it reliable in monsoon and high-risk climate conditions.

XRTech integrates hyperspectral satellite imaging to monitor environmental risks, including water contamination, heavy metal presence, turbidity changes, and ecosystem degradation around tailings reservoirs.

Historical satellite archives dating back to 1999 allow mining operators to analyze long-term deformation trends, land subsidence, and environmental impact patterns.

AI-driven early warning systems automatically flag terrain stress indicators and deformation acceleration, strengthening proactive risk mitigation and compliance with global tailings standards.

Effective Tailings Dam Monitoring requires a multi-sensor ecosystem combining InSAR, SAR, hyperspectral imaging, and AI analytics to prevent failures, protect communities, and ensure regulatory compliance.